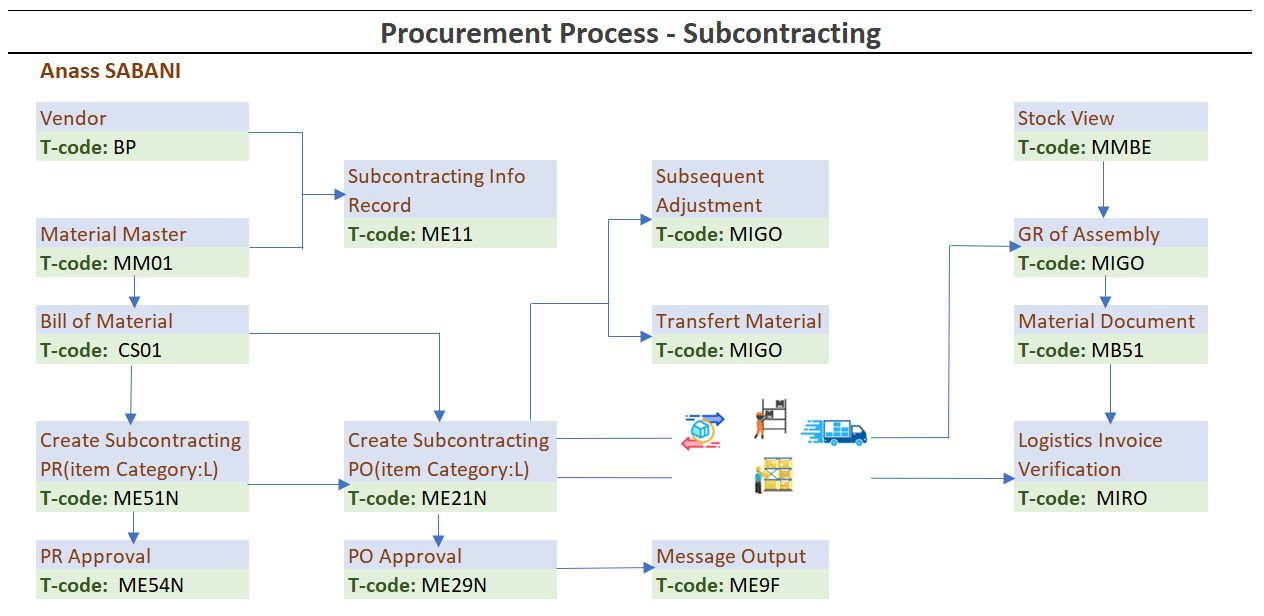

This flow diagram outlines the procurement process specifically for subcontracting in SAP, detailing different stages with their associated transaction codes (T-codes).

SAP MM Subcontracting Process Breakdown with T-codes:

- Vendor and Material Setup:

-

- Vendor (BP) 👤: Set up or choose a vendor using the Business Partner (BP) T-code.

- Material Master (MM01) 📦: Create or manage the master data for the materials used in subcontracting.

- Subcontracting Info Record (ME11) 📄: Define details about the subcontracting relationship, such as pricing and lead times.

- Bill of Material (CS01) 🛠️: Create and manage the Bill of Materials (BOM) to outline component requirements for the final product.

- Subcontracting Purchase Requisition (Inquiry) and Order:

-

- Create Subcontracting PR (ME51N) 📝: Initiate a Purchase Requisition for subcontracting items.

- PR Approval (ME54N) ✅: Approve the purchase requisition for further processing.

- Create Subcontracting PO (ME21N) 🛒: Convert the approved requisition into a Purchase Order with subcontracting item category “L”.

- PO Approval (ME29N) ✅: Final approval for the subcontracting Purchase Order.

- Message Output (ME9F) ✉️: Generate communication messages related to subcontracting procurement, such as order confirmations.

- Material Transfer, Goods Receipt and Invoice Verification (LIV):

-

- Stock View (MMBE) 📊: View and analyze stock levels to assess material availability.

- Transfer Material to Subcontractor (MIGO) ➡️: Issue the required materials to the subcontractor as per the Purchase Order.

- Subsequent Adjustment (MIGO) ⚙️: Adjust and manage the subsequent changes in subcontracting materials.

- GR of Assembly (MIGO) 📦: Record the receipt of the finished assembly from the subcontractor.

- Material Document (MB51) 📑: View or manage material documents created in the process.

- Logistics Invoice Verification (MIRO) 🧾: Verify the invoice against the Purchase Order and received goods.