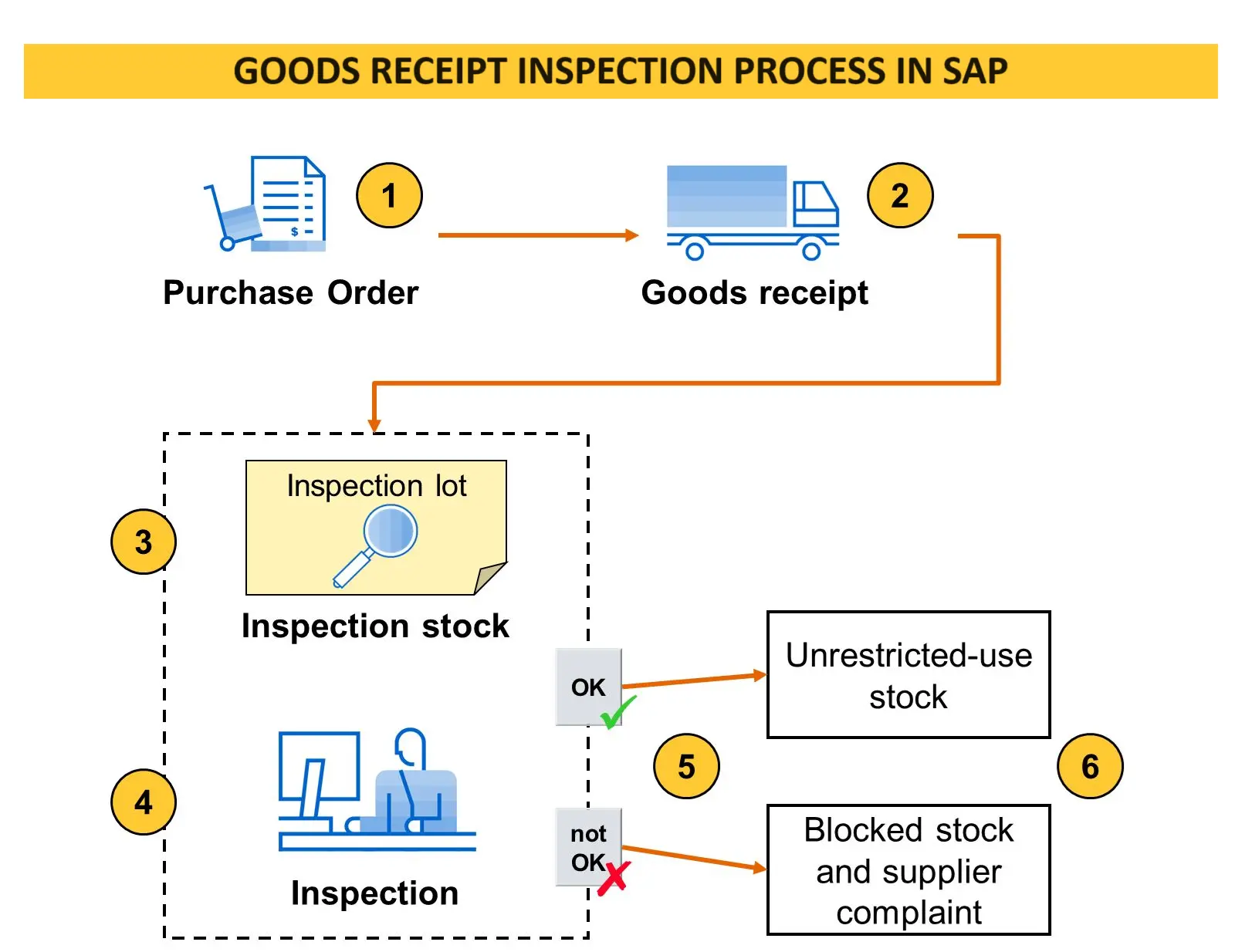

This Goods Receipt Inspection Process in SAP ensures incoming materials meet quality standards before they’re used in further production or distribution. Here’s a structured breakdown of the process:

- Purchase Order Creation in SAP 🛒:

- The procurement department issues a purchase order that specifies material requirements.

- Goods Receipt in SAP🚚:

- Upon goods arrival, the warehouse clerk confirms the receipt in the system.

- If inspection is required for the material, an inspection lot is automatically generated.

- This inspection lot contains key details like the purchase order item, material, and received quantity.

- The materials are placed in inspection stock until quality checks are complete.

- Inspection Stock 🔍:

- The materials in this stock are temporarily restricted from further processes.

- Inspection 👨💻:

- Quality technicians inspect the materials based on the predefined inspection plan.

- Two approaches are employed:

- Standard Inspection: Follows a detailed plan with specific checks and records results.

- Exception-Based Inspection: Focuses on deviations, documenting defects comprehensively.

- Both approaches can be combined for a thorough inspection.

- Usage Decision (UD) – Positive ✅:

- If the quality checks are successful, the material is moved to unrestricted-use stock for further processes.

- Usage Decision (UD) – Negative ❌:

- If issues are found, the material is moved to blocked stock, and the supplier is notified through a quality complaint process.

This process integrates both automated and manual quality controls to ensure that only high-quality materials are accepted and used.