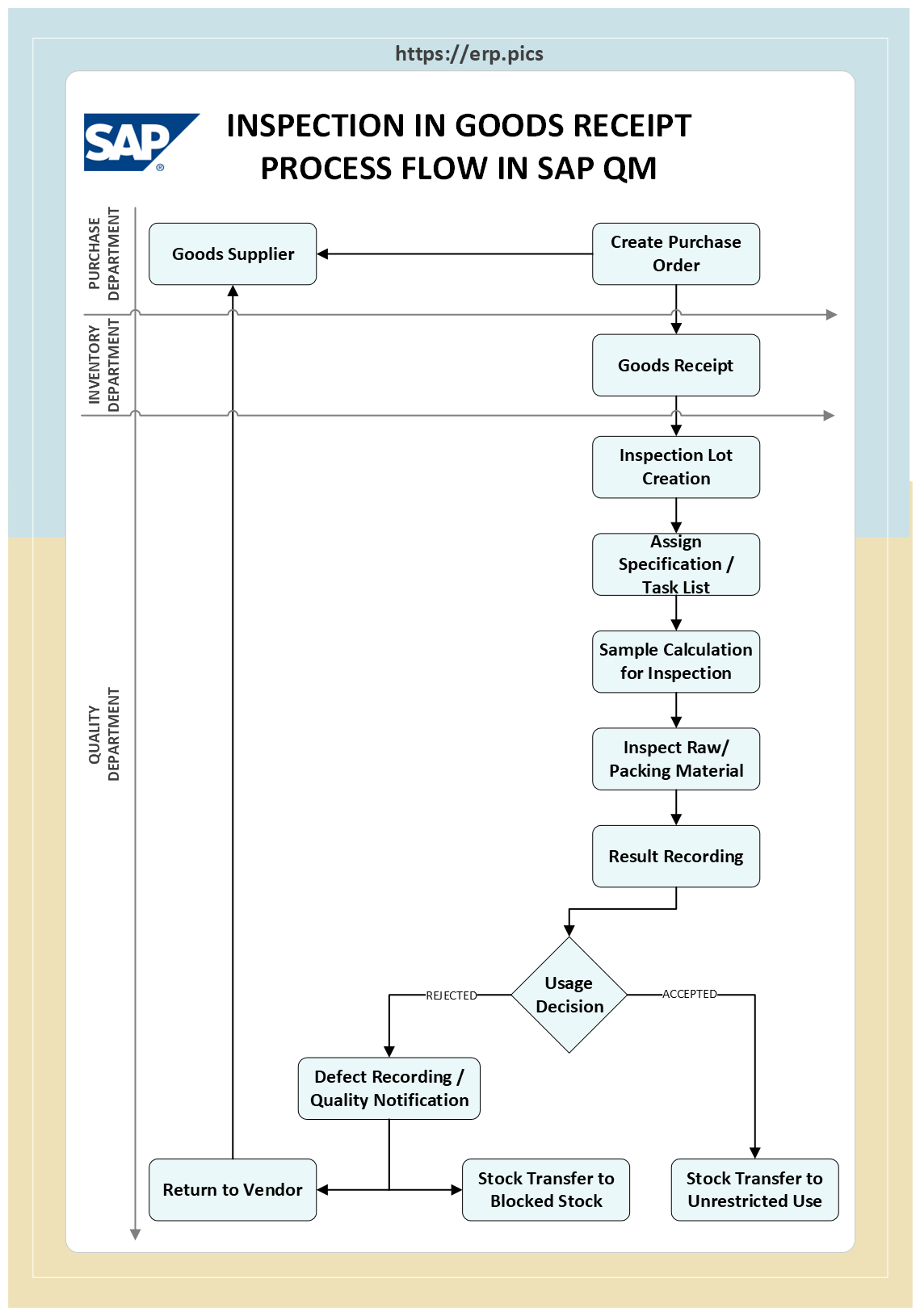

This business process flowchart outlines the inspection of raw or packing materials to ensure they meet defined quality requirements. The inspection process is integrated into SAP QM and involves several key steps from the receipt of goods to the final usage decision and stock posting.

Flowchart Diagram Breakdown:

- Create Purchase Order 📝: The purchasing department initiates the process by creating a purchase order.

- Goods Receipt 📦: Upon receipt of the goods from the supplier, the inventory department records the goods receipt in the system.

- Inspection Lot Creation 🔍: An inspection lot is created either manually or automatically upon goods receipt.

- Assign Specification/Task List 📄: The inspection specification is assigned to the inspection lot, which is necessary for entering results and making a usage decision. This can be done manually by a user or automatically by the system based on various criteria.

- Sample Calculation for Inspection 🧪: The sample size for the inspection lot is calculated, which can be done either manually or automatically using predefined sampling procedures.

- Inspect Raw/Packing Material 🛠️: The actual inspection of the raw or packing material is conducted using selected methods and equipment.

- Result Recording 📝: The results of the inspection characteristics are recorded in the system. This data is used for documentation and quality control purposes.

- Usage Decision ✅❌: Based on the recorded inspection results, a decision is made whether to accept or reject the materials. If accepted, the process continues to stock posting. If rejected, the process may involve defect recording and quality notification.

- Defect Recording/Quality Notification 🚨: If defects are found during inspection, they are recorded using predefined defect codes and saved as a quality notification in the system.

- Stock Posting 🏷️: Depending on the usage decision, the quality stock is transferred into the relevant stock categories:

- Unrestricted: For materials that passed inspection.

- Blocked: For materials that need further evaluation or are not usable.

- Return to Vendor: For materials that are rejected and need to be sent back to the supplier.

This structured SAP QM Quality Inspection process flow ensures that all incoming raw and packing materials are consistently inspected and meet quality standards before being used in production or other processes.