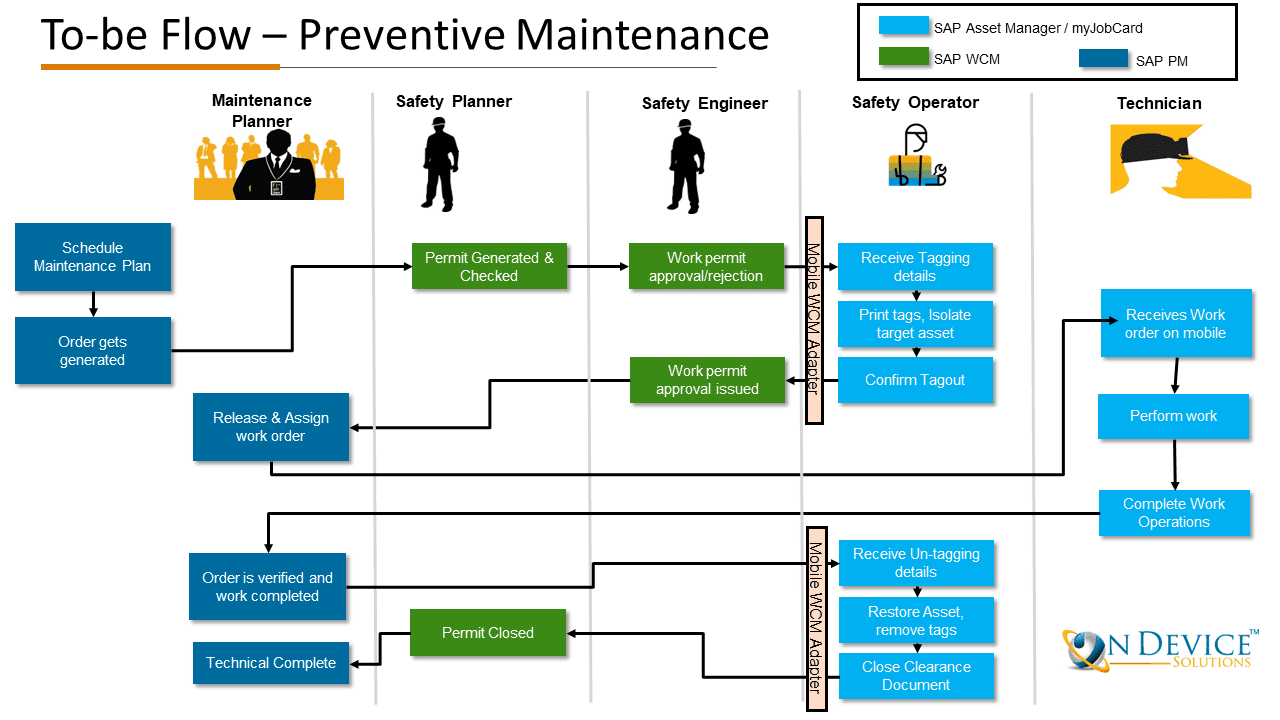

This flowchart illustrates the preventive maintenance workflow within the SAP system integration with Work Clearance Management (Permit to Work) procedures like Work Permits and Lock Out-Tag Out (LOTO). It is a systematic process that begins with the planning of maintenance activities and concludes with the completion and documentation of the tasks, ensuring both operational efficiency and adherence to safety protocols.

SAP Preventive Maintenance Process Flow with WCM Integration:

- Schedule Preventive Maintenance Plan 🗓️: The process initiates with scheduling a maintenance plan, outlining the preventive measures to be taken for equipment or machinery.

- Order Generation 📝: Following the schedule, a maintenance order is automatically generated, encapsulating the details and requirements of the maintenance tasks.

- Work Permit Creation 🛡️: A safety work permit is then created in SAP and subjected to a thorough check to ensure compliance with safety standards.

- Work Permit Evaluation ✅: The work permit undergoes an evaluation process where it is either approved or rejected by the responsible authority.

- Work Permit Issuance 📜: Upon approval, the work permit is officially issued, allowing the maintenance activities to commence.

- Tagging Procedure 🏷️: Tagging details are received, which involve printing and attaching tags to the equipment to clearly mark it for maintenance, ensuring it is isolated from normal operations.

- Tagout Confirmation 🔒: The safety operator confirms the tagout, signifying that the equipment is safely isolated and ready for maintenance.

- Work Order Receipt on Mobile 📱: Technicians receive the work order on their mobile devices, equipping them with all necessary information to perform the tasks.

- Maintenance Work Order Execution 🔧: The technicians carry out the maintenance work as specified in the work order.

- Maintenance Work Order Completion ✨: Upon finishing the maintenance tasks, the technicians complete the work operations, marking the physical completion of the maintenance activities.

- Untagging Process ↔️: Following the completion of maintenance, untagging details are received to restore the asset to its operational state.

- Asset Restoration and Tag Removal ⚙️: The asset is then restored, and the safety tags are removed, signaling that the equipment can be safely put back into use.

- Closure of Work Permit 📕: The process concludes with the closure of the work permit, ensuring that all safety procedures have been duly followed and documented.

- Technical Completion and Order Verification ✔️: The maintenance order is verified for accuracy and completeness, and the technical completion is documented in the system.

- Permit and Order Settlement 📊: The closed work permit and the completed order are settled in the system, providing a traceable history of the maintenance activity for future reference and compliance.

This comprehensive process flow ensures a cohesive and safe approach to preventive maintenance, facilitated by the SAP PM system and complemented by the integration with SAP WCM for managing work clearances.