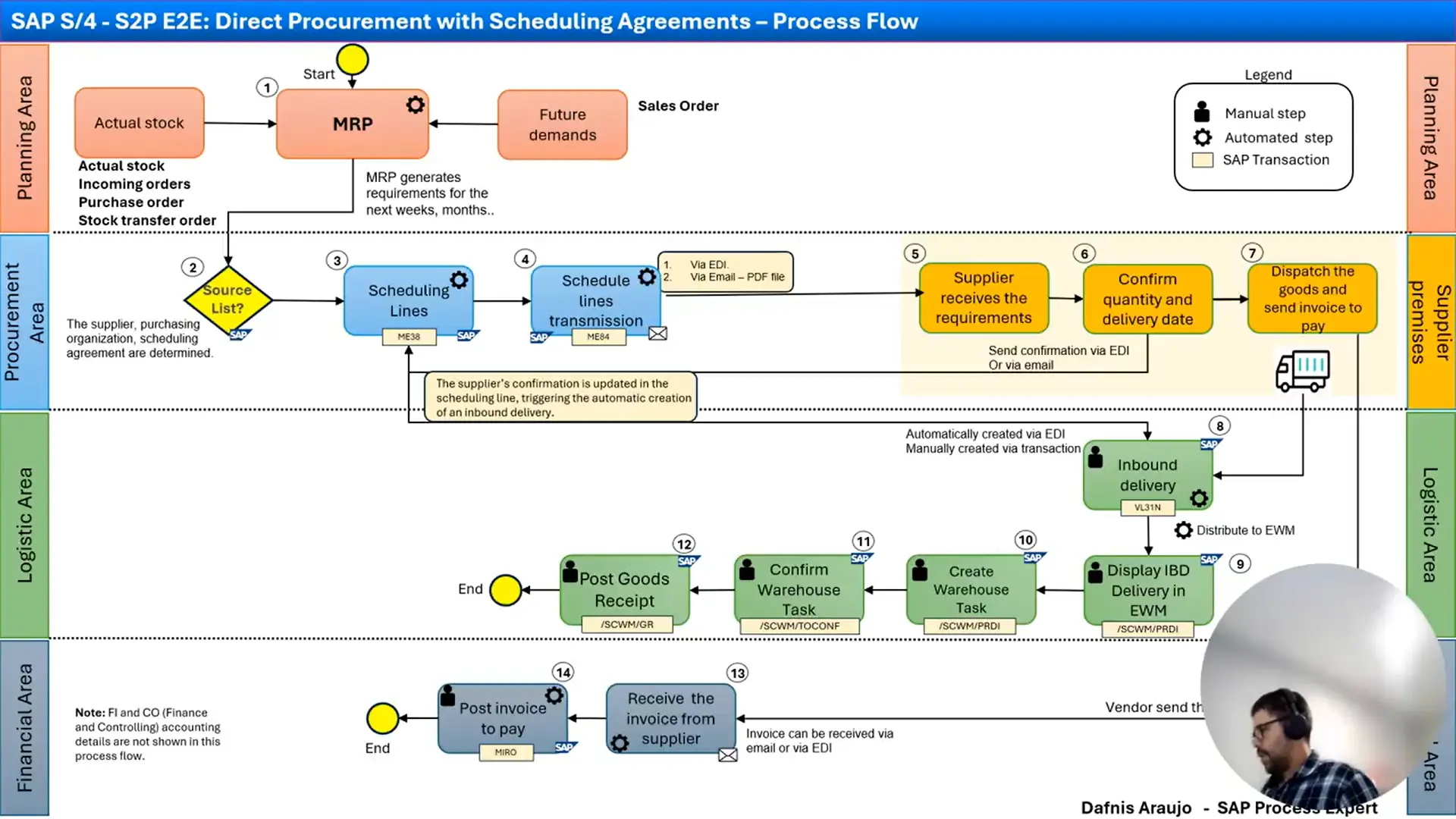

This flowchart, provided by Dafnis Araujo, depicts the end-to-end (E2E) process for direct procurement within an SAP S/4HANA environment, specifically when utilizing scheduling agreements. It outlines the sequence of activities from material requirements planning through to invoice payment, highlighting key system transactions, manual interventions, and interactions between different business areas (Planning, Procurement, Supplier, Logistics, and Finance).

Direct Procurement with Scheduling Agreements Definition in SAP ERP: Direct Procurement with Scheduling Agreements refers to the business process of acquiring raw materials or components that are directly used in the production of a company’s goods. Scheduling Agreements are long-term outline agreements with a supplier for the provision of materials or services according to predetermined conditions, quantities, and delivery dates, which are then communicated via schedule lines. This method facilitates a streamlined and often automated replenishment process for critical production inputs.

Process Flow Description:

The process is organized into distinct areas: Planning, Procurement, Supplier Premises, Logistic, and Financial.

- Planning Area:

- 1. MRP (Material Requirements Planning): The process commences with an automated MRP run. This step “checks the actual stock” (which includes current inventory, incoming orders, purchase orders, and stock transfer orders) and considers “future demands” (often derived from Sales Orders). Based on this analysis, the MRP “generates requirements for the next weeks, months…” for suppliers. These requirements for supply can be established on a weekly or monthly basis, depending on the specific system setup and strategy.

- Procurement Area:

- 2. Source List?: Following the MRP run, a manual decision step occurs where the system checks the “Source List?”. This is where a valid supplier and scheduling agreement are verified, and “The supplier, purchasing organization, scheduling agreement are determined.”

- 3. Scheduling Lines: If a valid source and scheduling agreement are found, the system automatically generates “Scheduling Lines” (SAP Transaction: ME38). These schedule lines represent the MRP-driven requirements.

- 4. Schedule lines transmission: These “Scheduling Lines” are then automatically transmitted to the supplier (SAP Transaction: ME84). The transmission can occur “1. Via EDI” or “2. Via Email – PDF file,” based on the system configuration.

- Supplier Premises:

- 5. Supplier receives the requirements: The supplier receives the transmitted schedule lines outlining the requirements.

- 6. Confirm quantity and delivery date: The supplier reviews the requirements and then “Confirm[s] quantity and delivery date.” This confirmation is sent back to the procuring organization, typically “via EDI Or via email.”

- 7. Dispatch the goods and send invoice to pay: After confirmation, the supplier dispatches the goods and subsequently sends an invoice for payment.

- Note: The flowchart indicates, “The supplier’s confirmation is updated in the scheduling line, triggering the automatic creation of an inbound delivery.” This update of confirmations in the schedule lines is a key step, and if EDI is used for these confirmations, the inbound delivery document can be automatically created.

- Logistic Area:

- 8. Inbound delivery: An “Inbound delivery” is created. This can be “Automatically created via EDI” (particularly when confirmations are received from the supplier via EDI) or “Manually created via transaction” VL31N. This inbound delivery is then “Distribute[d] to EWM” (Extended Warehouse Management).

- 9. Display IBD Delivery in EWM: The inbound delivery is then automatically displayed within the EWM system (SAP Transaction: /SCWM/PRDI), often appearing in a system monitor.

- 10. Create Warehouse Task: An automated step follows to “Create Warehouse Task” within EWM (SAP Transaction: /SCWM/PRDI) to initiate the goods receipt process.

- 11. Confirm Warehouse Task: The warehouse task, representing the physical putaway or handling of goods, is then manually confirmed (SAP Transaction: /SCWM/TO_CONF).

- 12. Post Goods Receipt: Following task confirmation, a “Post Goods Receipt” is manually executed (SAP Transaction: /SCWM/GR). This action signifies that the goods are received into the system and become available for stock. As a consequence, a material document and corresponding accounting documents are created.

- Financial Area:

- 13. Receive the invoice from supplier: The financial department receives the invoice from the supplier. This “Invoice can be received via email or via EDI.”

- 14. Post invoice to pay: The received invoice is then manually “booked in the system” for the financial department to process for payment (SAP Transaction: MIRO). This concludes the procurement process.

- Note: The flowchart mentions, “FI and CO (Finance and Controlling) accounting details are not shown in this process flow,” indicating that while accounting documents are generated, the detailed financial postings are beyond the scope of this particular diagram.