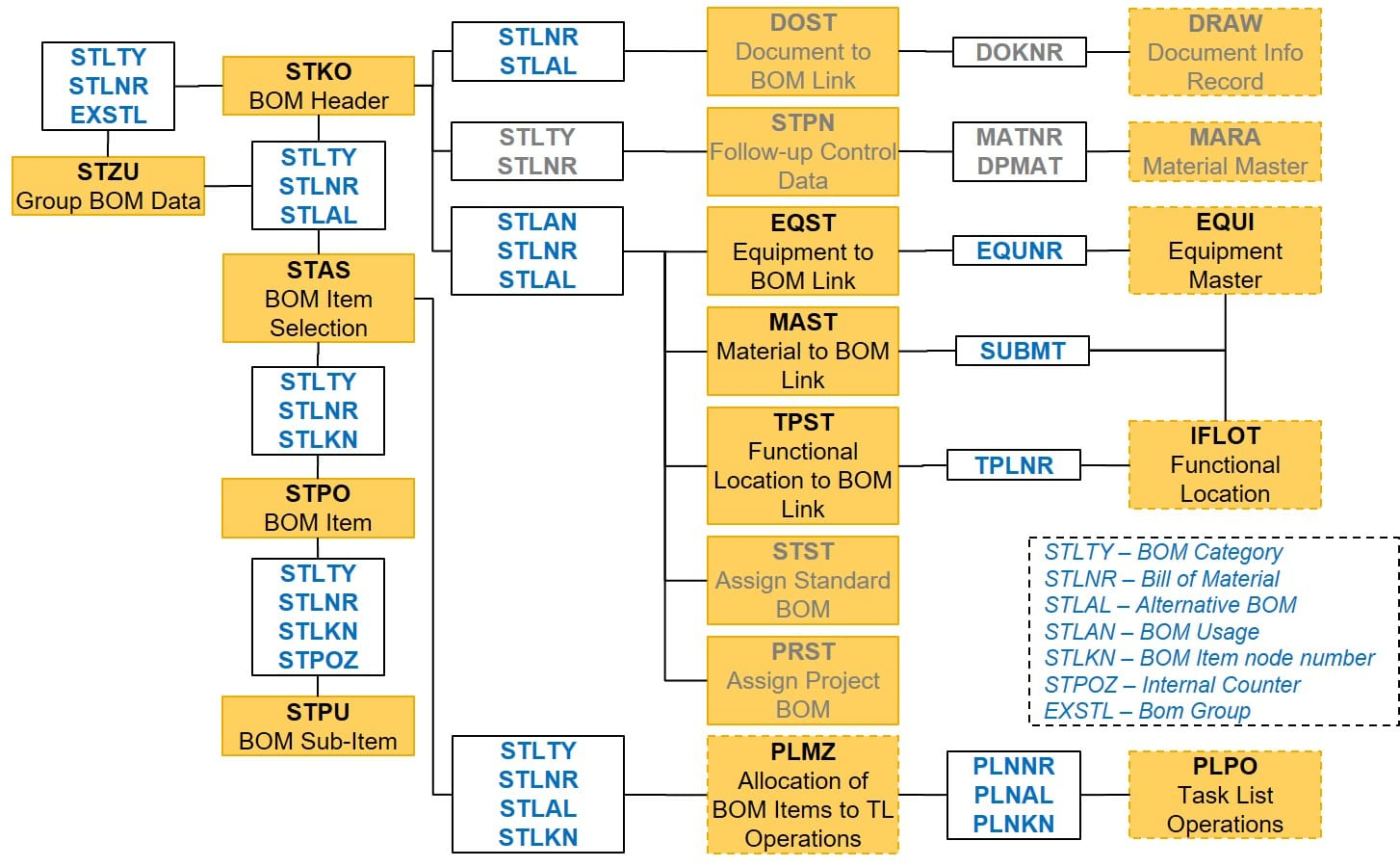

This diagram details the structure and connections of Bills of Materials (BOMs) in the SAP Plant Maintenance module, showcasing how different BOM types are interconnected and consolidated for technical objects like equipment, functional locations, and material assemblies. This is crucial for maintaining, planning, and managing maintenance tasks efficiently. Here’s a detailed breakdown:

Key Components and Their Interactions:

BOM Structure and Grouping

- STKO (BOM Header):

- Purpose: Serves as the header data for the BOM, including key elements like BOM category (STLTY) and number (STLNR).

- Key Fields: STLTY (BOM category), STLNR (BOM number), STLAN (BOM usage), and STAL (Alternative BOM). EXSTL identifies Group BOMS, linking individual BOMs under a common group ID.

- Interactions: Interfaces with several tables to connect an individual BOM with its components and group data. Primarily used to identify and separate Equipment, Material, and Functional Location BOMs.

- STAS (BOM Item Selection):

- Purpose: Manages the linkage between BOM items and the header.

- Key Fields: STLTY, STLNR, STLKNR, identifies exact linkage of an item within the BOM.

- Interactions: Aligns closely with STPO to refer to actual BOM contents.

- STPO (BOM Item):

- Purpose: Details each component or item within a BOM.

- Key Fields: STLTY, STLNR, STPOZ (line item counter).

- Interactions: This table is crucial for defining the complete list of BOM components, contains the specific material numbers, quantities, and other details.

- STPU (BOM Sub-Item):

- Purpose: Represents sub-items/assembly connections within a BOM, though not always used.

- Key Fields: Again linked with STLTY, STLNR, STLX – maintaining the hierarchical structure.

- STZU (Group BOM Data):

- Purpose: Manages the assignment and grouping of BOMs into a single group BOM.

- Key Fields: Links BOMs through EXSTL (BOM Group ID).

- Interactions: Essential for variants management where BOM setups are similar but vary by alternatives. Group BOMs allow for centralized BOM management, essential for clients managing diverse yet similar equipment assemblies.

Object Linkage to BOMs

- Equipment to BOM Link (EQST):

- Purpose: Connects equipment data with associated BOMs.

- Key Fields: EQUNR (equipment number).

- Interactions: Maps out how each piece of equipment utilizes specific BOMs and their components.

- Material to BOM Link (MAST):

- Purpose: Specifies how materials link to BOMs, typically for assemblies.

- Key Fields: Material number (MATNR).

- Interactions: Facilitates the linkage of material masters to corresponding BOMs, vital for planning and procurement processes.

- Functional Location to BOM Link (TPST):

- Purpose: Establishes connections between functional locations and BOMs.

- Key Fields: Functional Location (TPLNR).

- Interactions: Links fixed physical locations within a plant with BOMs. Useful where similar installations at different sites might benefit from shared components.

Additional Table Linkages

- PLMZ (Allocation of BOM Items to Task List Operations):

- Purpose: Aligns BOM components with task list operations, detailing which parts are required for specific maintenance operations.

- Interactions: Crucial for effectively managing and executing maintenance tasks on technical objects.

- DOST (Document to BOM Link) and DRAW (Document Info Record):

- Purpose: Connect documents to BOMs for comprehensive documentation.

- Interactions: Assures that all documentation, such as safety and usage instructions, are properly linked to relevant BOMs.

Practical Insights and Implementation

- Group BOMs: For managing similar BOMs with variations through the Group concept, allowing for efficient creation, modification, and tracking of both individual and grouped BOMs. However, managing up to 99 BOMs in a group can be cumbersome, demanding precise data setup and governance.

- Migration Challenges: Preparing BOMs for S/4HANA requires careful configuration, particularly in regard to the

Rptd itm effctvtyparameter that enables re-usability of item numbers across BOMs. - Load Files: Proper creation and categorization of load files based on the classification (Equipment, Material, Functional Location) facilitates smoother migration processes.

Conclusion:

This in-depth diagram and explanation provides a comprehensive framework for understanding BOM interactions SAP PM. It guides the setup, migration, and maintenance of complex BOM structures in large-scale operational environments. Ensuring data consistency and leveraging SAP’s grouping capabilities ensures streamlined operations and reliability in maintenance practices across industry sectors.