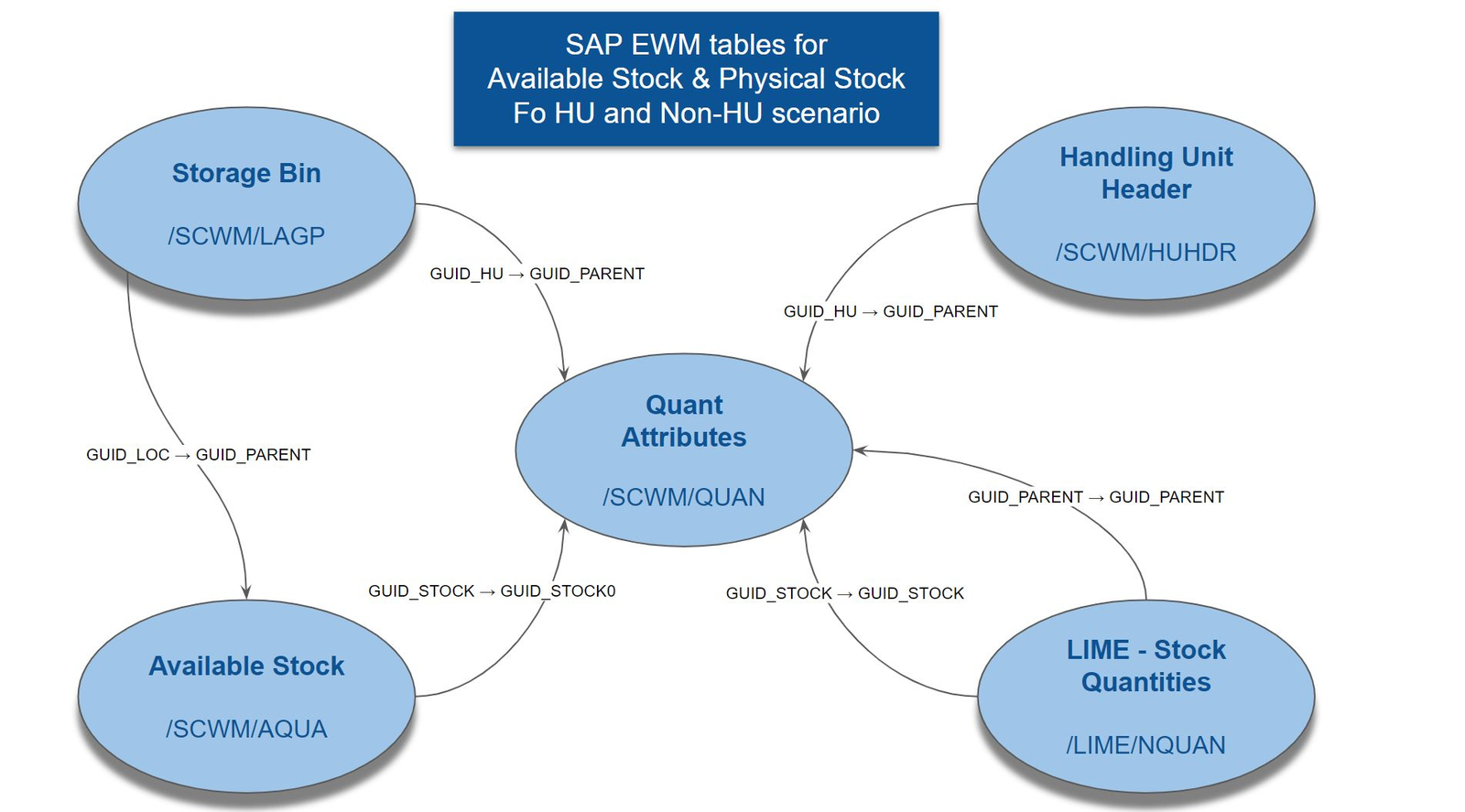

This image, provided by Makrand Kekre, illustrates the core SAP EWM (Extended Warehouse Management) tables used for managing stock in the warehouse, both for Handling Unit (HU) and Non-HU scenarios, utilizing the GUID (Globally Unique Identifier) system. Here’s related notes for the provided diagram table:

Overview:

SAP EWM heavily relies on the GUID concept, which serves as a unique identifier to track records across tables. This GUID system ensures the linkage between different types of stock data, handling units, and physical inventory, maintaining consistency across tables.

Main Tables in the Diagram:

- /SCWM/LAGP (Storage Bin):

- This table holds details of storage bins within the warehouse where stock is physically stored. Each bin has a unique

GUID_LOC(GUID for location), which links to the Quant Attributes table.

- This table holds details of storage bins within the warehouse where stock is physically stored. Each bin has a unique

- /SCWM/AQUA (Available Stock):

- This table contains information about the available stock in the warehouse, ready to be picked for tasks. It gets updated when a warehouse task is created, and the quantity here can even be negative based on warehouse configuration. When the stock quantity reaches zero, the entry is deleted. The table is connected to the Quant Attributes table using

GUID_STOCK, signifying stock availability at a detailed level.

- This table contains information about the available stock in the warehouse, ready to be picked for tasks. It gets updated when a warehouse task is created, and the quantity here can even be negative based on warehouse configuration. When the stock quantity reaches zero, the entry is deleted. The table is connected to the Quant Attributes table using

- /SCWM/QUAN (Quant Attributes):

- This is the heart of physical stock tracking. It stores all attributes related to a particular stock quantity, such as the goods receipt (GR) date, best before date, country of origin, and delivery references. This table is linked to both the Available Stock and Handling Unit tables via GUIDs (

GUID_HU,GUID_PARENT, andGUID_STOCK). Once the corresponding quantity in /LIME/NQUAN reaches zero, this entry is deleted. This table also plays a critical role in providing key details about the stock for physical inventory management.

- This is the heart of physical stock tracking. It stores all attributes related to a particular stock quantity, such as the goods receipt (GR) date, best before date, country of origin, and delivery references. This table is linked to both the Available Stock and Handling Unit tables via GUIDs (

- /SCWM/HUHDR (Handling Unit Header):

- This table stores the header details for handling units (HUs), which are containers or packages used to store and transport stock within the warehouse. HUs are a critical part of stock management in SAP EWM, especially for tracking and handling serialized items.

- /LIME/NQUAN (LIME Stock Quantities):

- This table represents the physical stock quantities reserved for open warehouse tasks. It can reflect a negative value, depending on whether negative stock is allowed in the storage type settings. The entry in this table is reduced to zero when a warehouse task is either confirmed or canceled. It is closely linked with the Quant Attributes table, and discrepancies between this table and /SCWM/QUAN often indicate stock management issues.

How These EWM Tables Interact:

- /SCWM/QUAN acts as the central table connecting /SCWM/AQUA (available stock) and /LIME/NQUAN (physical stock for warehouse tasks). It links through GUIDs (

GUID_STOCK,GUID_HU, andGUID_PARENT), ensuring coherence between available stock, reserved stock, and physical stock. - Handling Units (HUs) tracked by /SCWM/HUHDR are also connected through the Quant Attributes table via

GUID_HU. This linkage ensures that stock within handling units is properly recorded and accounted for.

Key Points about Stock and Handling Units:

- Any discrepancies between these tables may cause issues in warehouse operations such as inventory mismatch or incorrect stock statuses. For example, inconsistencies between /SCWM/AQUA and /LIME/NQUAN may affect the ability to create warehouse tasks or process internal movements, while inconsistencies in Handling Unit data (tracked by /SCWM/HUHDR) could lead to problems during goods receipt or dispatch processes.

Handling Unit-Related Tables (Beyond the Diagram):

In addition to /SCWM/HUHDR (Handling Unit Header), other important Handling Unit-related tables in SAP EWM include:

- /SCWM/GMHUIDENT: Additional Handling Unit Identifications for goods movements.

- /SCWM/HUSSTAT: Individual status for each handling unit.

- /SCWM/HUREF: Handling Unit reference.

- /SCWM/GMHUSTAT: Handling Unit status during goods movement.

- /SCWM/GMHUHDR: Goods movement handling unit header.

Discrepancies between stock tables and Handling Unit tables (such as those mentioned above) can cause significant problems in various processes, including inventory management, inbound and outbound deliveries, and internal warehouse movements. Therefore, it is essential to maintain data consistency across all these tables, with GUIDs serving as the fundamental link.

All above descriptions highlights the importance of GUIDs, the relationship between available and physical stock, and how SAP EWM handles stock management through its complex table structure.