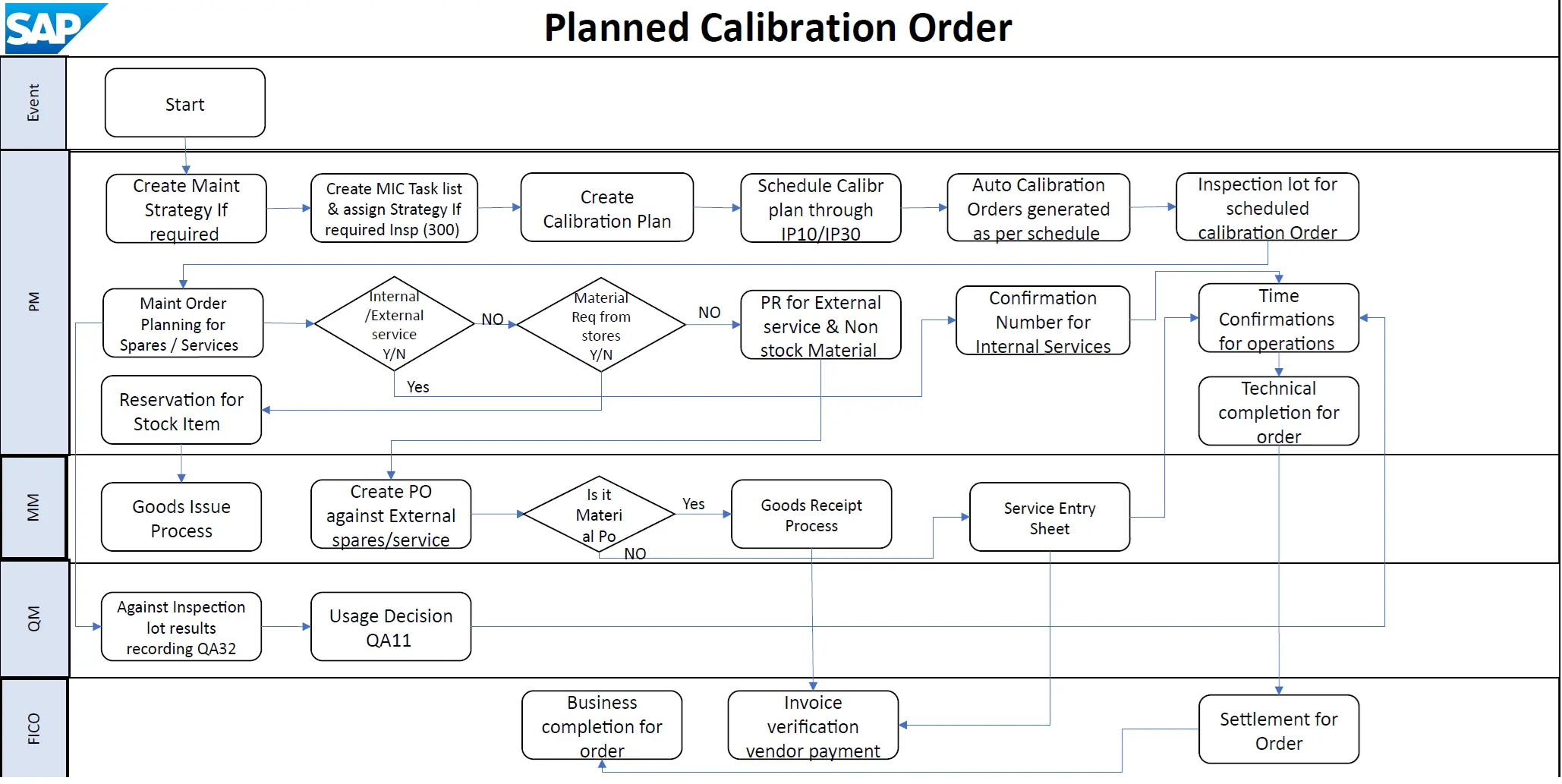

The flowchart illustrates the Planned Calibration MAintenance Order process within the SAP system, integrating modules such as Plant Maintenance (PM), Materials Management (MM), Quality Management (QM), and Financial Accounting & Controlling (FICO). Below is a detailed breakdown of the process:

🛠️ Plant Maintenance (PM) Activities

- Create Maintenance Strategy If Required (Transaction: IP11): The overall approach for calibration maintenance is defined.

- Create MIC Task List & Assign Strategy If Required Insp (300) (Transaction: IA05 or IA06): A Master Inspection Characteristic (MIC) task list is created and assigned to the maintenance strategy. The inspection (300) type is specified, designating the activities as calibration-related tasks.

- Create Calibration Plan (Transaction: IP41 or IP42): A calibration plan is established to schedule regular calibration activities, ensuring that all equipment is maintained within the specified intervals.

- Schedule Calibration Plan (Transaction: IP10 or IP30): The calibration plan is scheduled and activated, setting the stage for automatic generation of calibration orders based on the defined timeline.

- Auto Calibration Orders Generated as per Schedule: Calibration orders are automatically created based on the scheduled intervals, streamlining the process and reducing the risk of missed or delayed calibrations.

- Inspection Lot for Scheduled Calibration Order (Transaction: QA32): An inspection lot is created for each scheduled calibration order, enabling the tracking and management of calibration results.

- Maintenance Order Planning for Spares/Services: Planning for required spares or services for the calibration is performed, ensuring that all necessary resources are available when needed.

- Internal/External Service Decision: A decision is made whether the calibration service will be performed internally by the organization’s technicians or outsourced to external service providers, based on factors such as expertise, availability, and cost-effectiveness.

- Confirmation Number for Internal Services: A confirmation number is generated for internal services is used for calibration service, providing a unique identifier for tracking and reporting purposes.

- Material Available from Stores Decision: A decision is made if materials are required from the organization’s stores or if additional procurement is necessary.

- Reservation for Stock Item (Transaction: MB21): If materials are required from the organization’s stores, a reservation for stock items is created, ensuring that the necessary components are set aside for the calibration process.

- PR for External Service & Non-stock Material: If external service or non-stock materials are needed, a purchase requisition is created, initiating the procurement process and ensuring that all required resources are obtained in a timely manner.

- Time Confirmations for Operations (Transaction: IW41): The time spent on calibration activities is recorded.

- Technical Completion for Order (Transaction: IW32): The calibration order is marked as technically complete, signifying that all necessary calibration activities have been performed and the equipment is ready for use.

📦 Materials Management (MM) Actions

- Goods Issue Process (Transaction: MB1A): Materials are issued against reservation for the calibration process when stock material is decided to use.

- Create PO against External Spares/Service (Transaction: ME21N): A purchase order is created for external spares when no stock material available from store or when no internal service is decided to use and decided to procure services externally.

- Goods Receipt Process (Transaction: MIGO): Goods receipt is recorded against purchase order.

- Service Entry Sheet (Transaction: ML81N): Services provided by external vendors are recorded against purchase order.

🔍 Quality Management (QM) Steps

- Against Inspection Lot Results Recording QA32: Based on the master inspection characteristic parameters and sampling procedure, the inspection lot is processed. The results of the calibration inspection are recorded against the corresponding inspection lot, providing a comprehensive record of the calibration process and its outcomes.

- Usage Decision QA11: Based on the readings/observations, the Maintenance personnel provide a usage decision on what action needs to be taken on this equipment, i.e. whether the equipment can be used, cannot be used or some adjustment/repair is required.

💰 Finance/Controlling (FICO) Steps

- Invoice Verification Vendor Payment (Transaction: MIRO): Vendor invoices for external services or materials are processed and verified.

- Settlement for Order (Transaction: KO88): Costs associated with the calibration order are settled.

📚 Related SAP Documentation:

- SAP PM/EAM Video Tutorial: Calibration Inspection

- Calibration of Test Equipment in SAP PM: Step-by-Step Guide

- SAP S/4HANA PM Calibration Maintenance: End User Manual

This planned calibration order process in SAP demonstrates the comprehensive approach to managing equipment calibration, ensuring accuracy and reliability of measuring instruments while integrating various SAP modules for efficient execution and cost control.