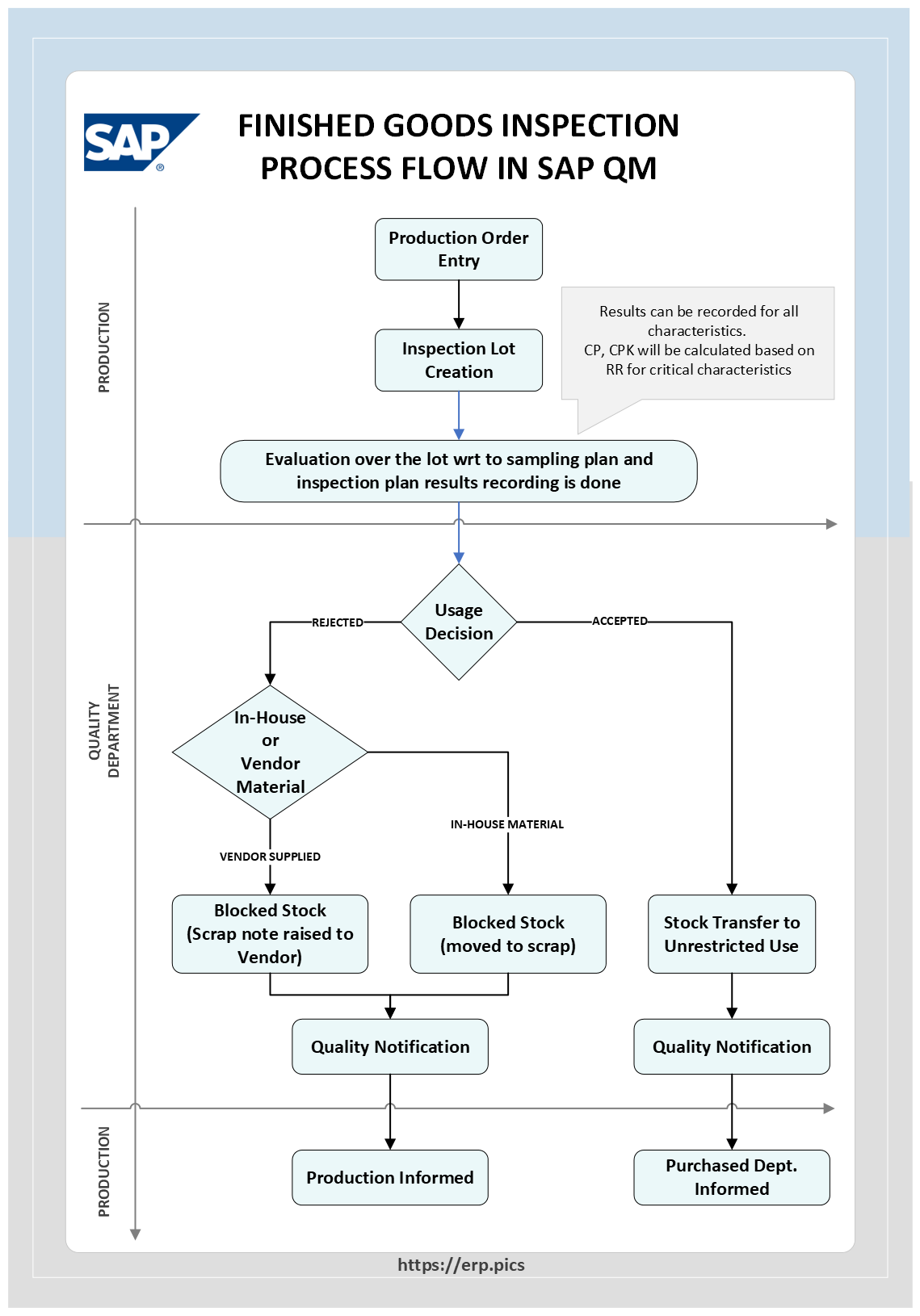

This flowchart illustrates the process of finished goods inspection in the SAP Quality Management (QM) module. The steps ensure that the production lot meets all quality parameters before it is accepted or rejected.

- Production Order Entry 📝: Quality control personnel receive information from production to audit a lot through the production order.

- Inspection Lot Creation 🛠️: An inspection lot is created for the produced items, initiating the quality check process.

- Evaluation of Lot 📊: The lot is evaluated against the sampling plan. Quality personnel record results for all characteristics. Critical characteristics are assessed using CP (Process Capability) and CPK (Process Capability Index) calculations.

- Usage Decision ⚖️: Based on the evaluation, a usage decision is made:

-

- Rejected ❌

- If vendor-supplied 🚚: Finished Goods moved to Blocked Stock (Scrap note raised to Vendor). A scrap note is raised and communicated to the vendor.

- If in-house 🏭: Finished Goods moved to Blocked Stock (Moved to Scrap).

- Quality Notification 📢: A quality notification is created to inform the production department of the rejection.

- Production Informed 📜: The production department is informed of the quality issue.

- Accepted ✔️

- Stock Transfer to Unrestricted Use 🔄: The accepted stock is transferred to unrestricted use, making it available for packaging and further processes.

- Quality Notification 📢: A quality notification is generated to inform the purchasing department of the acceptance.

- Rejected ❌

-

- Post Quality Check Process 🚧

- Until the quality check is done, the finished goods (e.g., pins, bushes) are not allowed for packaging.

- The FG material is stored physically at stores until the lot is accepted for all sampling parameters as per the sampling plan.

- Once accepted, the quality personnel make the results recording entry and issue the material for packaging through the usage decision.

This process ensures that only materials that meet the required quality standards are moved to unrestricted use and packaged, while rejected materials are appropriately handled and communicated to relevant departments.