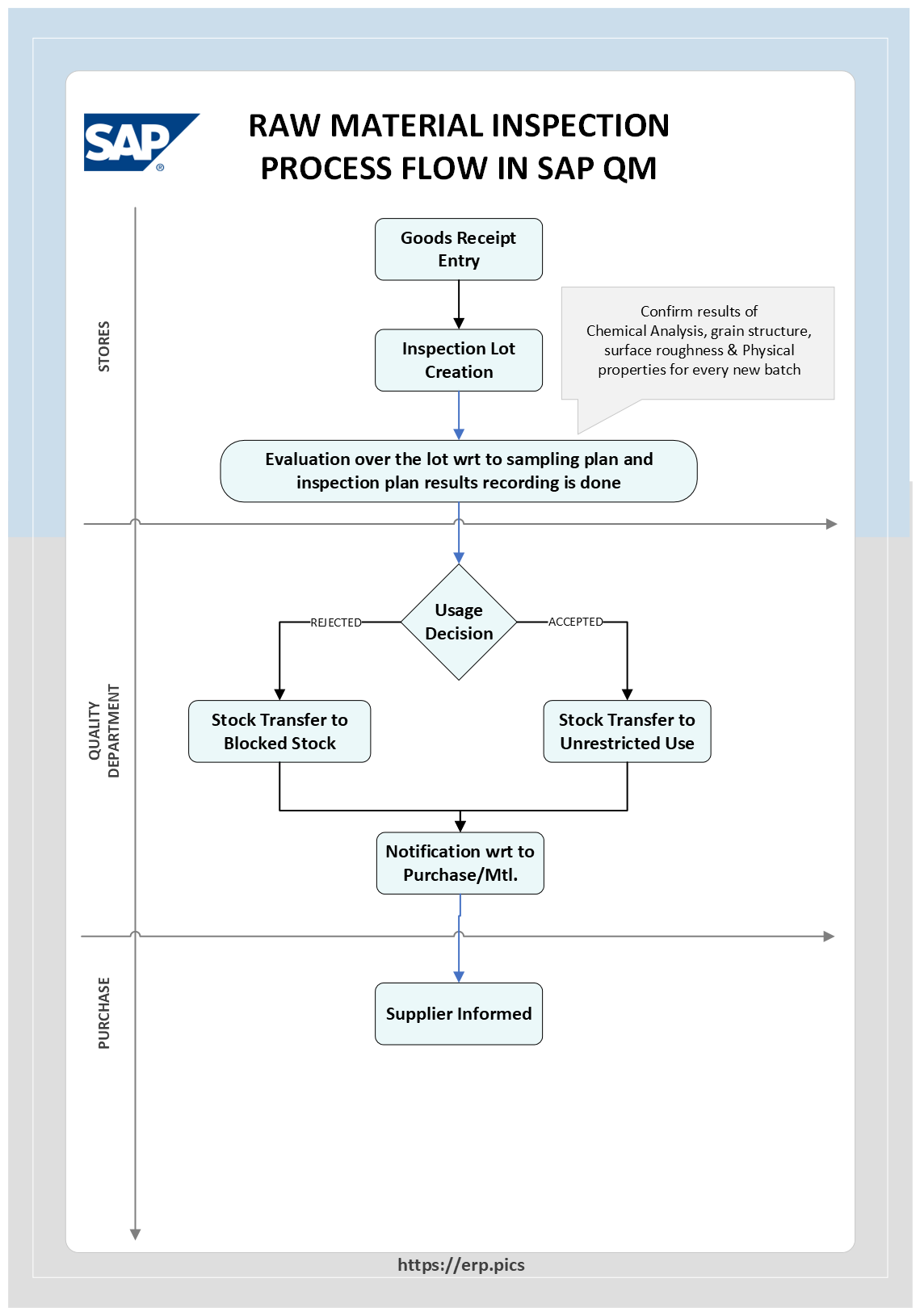

This flowchart outlines the process of inspecting raw materials in SAP Quality Management (QM). It covers the entire lifecycle of quality inspection from the goods receipt of incoming raw materials to the final usage decision. The process ensures that raw materials meet specified quality standards through detailed chemical and physical analysis. Based on the inspection results, materials are either accepted for production or rejected and transferred to blocked stock for return to the supplier.

- Goods Receipt Entry 📦: Raw material inspection starts when a Goods Receipt (GR) is made for an incoming product. This generates a raw material inspection lot. Inspection settings are maintained in the material master to ensure the correct characteristics are inspected according to material specifications.

- Inspection Lot Creation 📝: An inspection lot is generated, and this lot includes a set of results that need to be recorded and attached to every operation where Quality Assurance (QA) is involved. This ensures traceability and compliance with quality standards. This is typically done using the transaction code QA01 (Create Inspection Lot). To view the inspection lots that have been created, you can use QA32 (Change Inspection Lot). This transaction allows you to see all inspection lots, including their status and any user decisions made regarding their acceptance or rejection

- Chemical and Physical Analysis ⚗️: For every new batch, a chemical analysis and physical properties report is generated. This involves confirming results for chemical analysis, grain structure, surface roughness, and other physical properties.

- Evaluation of Inspection Lot 🔍: The inspection lot is evaluated against the sampling plan and inspection plan results are recorded. This step ensures the raw material meets the required specifications.

- Usage Decision 🔄: After inspecting the materials, a user decision is required to determine if the materials are acceptable. This can be done in QA32 transaction code where you can choose to accept or reject the material based on the inspection results. The status of the inspection lot will change accordingly (e.g., from “Released” to “User Decision”). The results of the inspection can be recorded using QA11 (Record Results). This is where the actual measurements and observations are documented. If the material meets the specifications, it is accepted; otherwise, it is rejected.

- Stock Transfer to Blocked Stock ❌: If the material does not meet the specification limits, it is rejected. The lot is posted as a rejection, and the raw material is moved to blocked stock for return delivery.

- Stock Transfer to Unrestricted Use ✅: If the material is within the specification limits, it is accepted. The quality personnel make the results recording entry and issue the material to production through a usage decision.

- Notification to Purchase/Material 📧: If any defects are found during the inspection, a quality notification can be created using QM01 (Create Quality Notification). This helps in tracking issues and initiating corrective actions.

- Supplier Informed 📞: The supplier is informed about the rejection and necessary actions are taken for the return of the defective raw material.