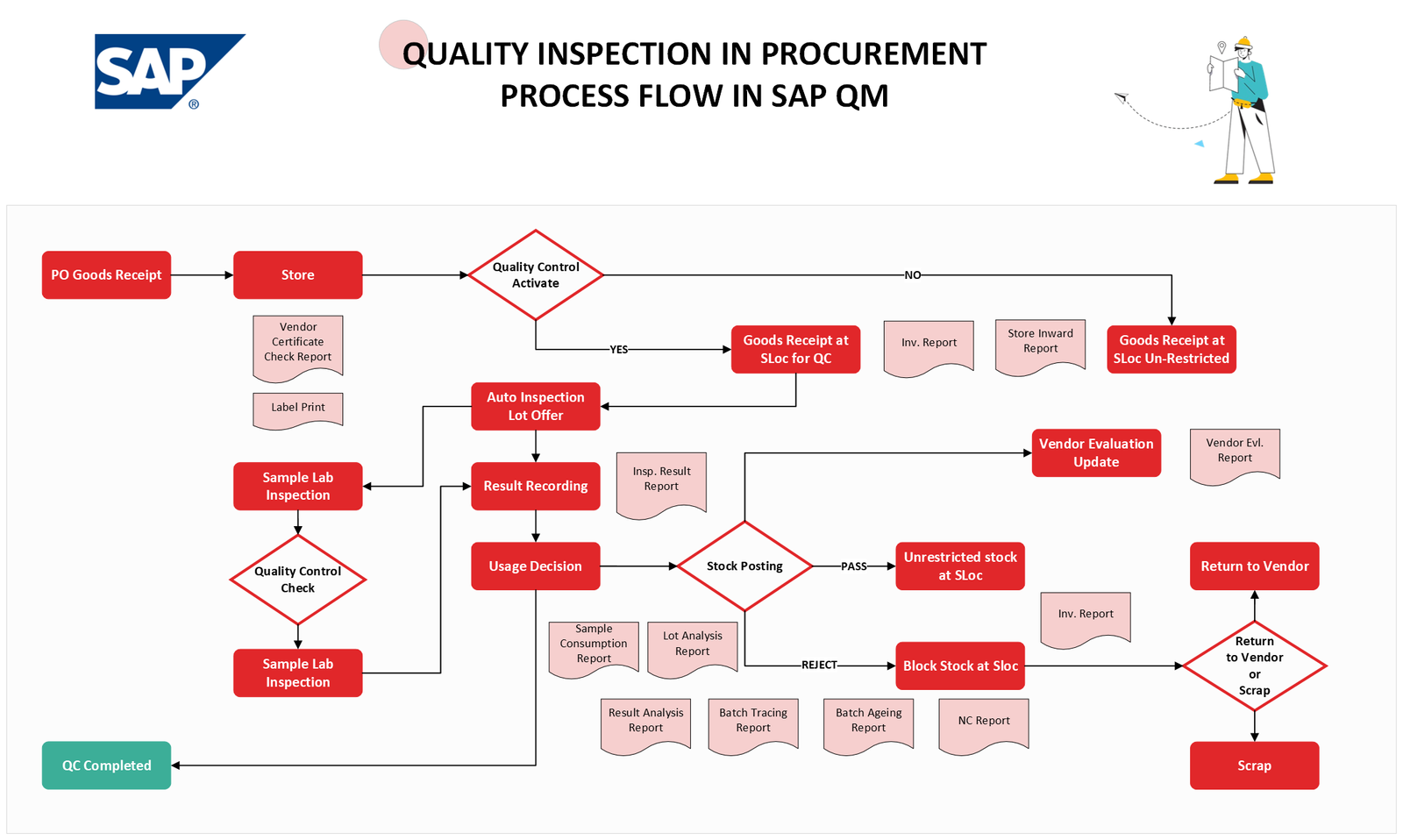

This flowchart illustrates the quality inspection process for goods received in SAP Quality Management (QM), outlining each step from the initial receipt of goods to the final stock posting and vendor evaluation. This process ensures that materials meet quality standards before being accepted into unrestricted stock, thereby maintaining inventory integrity and supplier accountability.

- PO Goods Receipt (MIGO): The process commences with the receipt of goods against Purchase Order (PO). This step involves entering the receipt details into the SAP system, which updates the inventory records and acknowledges the arrival of the materials. The creation of a goods receipt document is essential for tracking and managing received items.

- Quality Control Activation Decision: Upon receiving the goods, a critical decision point is reached where the system determines whether the received material requires quality inspection. This decision is based on predefined criteria such as material type, vendor agreements, or specific quality requirements. The outcome directs the flow to either a quality inspection process or a direct stock posting.

- Outcome:

- “NO” Branch: If quality control is not activated, the goods are directly posted to unrestricted stock, and the vendor evaluation is updated accordingly.

- “YES” Branch: If quality control is required, the process continues to the next step.

- Outcome:

- Auto Inspection Lot Offer: When quality control is activated, the system automatically generates an inspection lot for the materials received. This inspection lot serves as a reference for conducting quality checks and is linked to the specific batch of goods received.

- Importance: Automating the creation of inspection lots streamlines the quality inspection process, reducing manual intervention and minimizing errors.

- Goods Receipt at Storage Location (SLoc) for Quality Control: Goods that require quality inspection are moved to a designated storage location specifically allocated for quality control purposes. This temporary storage ensures that the materials are isolated for thorough inspection without affecting unrestricted stock levels.

- Purpose: Facilitates organized and efficient quality checks by segregating inspected and non-inspected materials.

- Result Recording (QE01): A quality technician conducts the inspection as per the defined inspection plans and records the results in the SAP system. This step involves documenting various quality characteristics and measurements to assess the conformity of the received materials.

- Details Recorded: Inspection results, deviations, and any non-conformities identified during the quality check.

- Usage Decision (QA11): A quality engineer reviews the recorded inspection results and makes a usage decision regarding the received materials. This decision determines whether the materials are accepted, rejected, or require further action.

- Possible Decisions:

- Accept: Materials meet quality standards and are posted to unrestricted stock.

- Reject: Materials do not meet quality standards and are moved to blocked stock.

- Further Action: Additional testing or evaluation may be required.

- Possible Decisions:

- Stock Posting Decision: Based on the usage decision, the system executes the appropriate stock posting. This step is crucial for maintaining accurate inventory records and ensuring that materials are available for use or appropriately managed if rejected.

- Stock Types Affected:

- Unrestricted Stock: For accepted materials.

- Blocked Stock: For rejected materials, preventing their use until further action is taken.

- Stock Types Affected:

- Stock Posting & Handling: The final stock posting is executed based on the usage decision. The accepted materials are moved to unrestricted stock, making them available for use in production or sales. Rejected materials are transferred to blocked stock, where they can either be returned to the vendor or scrapped, depending on the severity of the quality issues.

- Handling Options for Rejected Materials:

- Return to Vendor: If the materials can be sent back to the supplier for replacement or credit.

- Scrap: If the materials are deemed unusable and need to be disposed of.

- Handling Options for Rejected Materials:

- Vendor Evaluation Update: The quality of the received goods is assessed, and the vendor evaluation is updated accordingly. This evaluation provides valuable feedback to the vendor regarding their performance and quality standards.

- Purpose: Enhances supplier accountability and helps in making informed decisions for future procurement based on vendor reliability and quality performance.

- QC Completed: This step signifies the completion of the quality control process. All necessary inspections, decisions, and postings have been finalized, ensuring that the materials received are appropriately managed based on their quality status.

-

- Outcome: The inventory reflects the current status of received goods, and any necessary actions regarding rejected materials are documented and executed.

-

Key Process Aspects:

- Automation: The process leverages automation for generating inspection lots, recording results, and updating vendor evaluations, thereby enhancing efficiency and reducing manual errors.

- Master Data Accuracy: Maintaining accurate master data for materials, inspection plans, and quality characteristics is fundamental to the smooth execution of the quality inspection process.

- Data Integration: Seamless integration of data across all steps ensures a comprehensive overview and accurate tracking of materials from receipt to final stock posting.

- Stock Management: Effective management of stock types (unrestricted, blocked) is crucial for maintaining inventory accuracy and ensuring material availability for production or sales.

- Vendor Quality: Regular updates to vendor evaluations based on received goods quality foster strong supplier relationships and drive continuous improvement in vendor performance.

- Streamlining: The process is designed to minimize manual intervention, promoting greater operational efficiency and consistency in quality management.

By following these detailed steps, organizations can ensure that their quality inspection process for received goods is thorough, efficient, and aligned with best practices in inventory and supplier management.