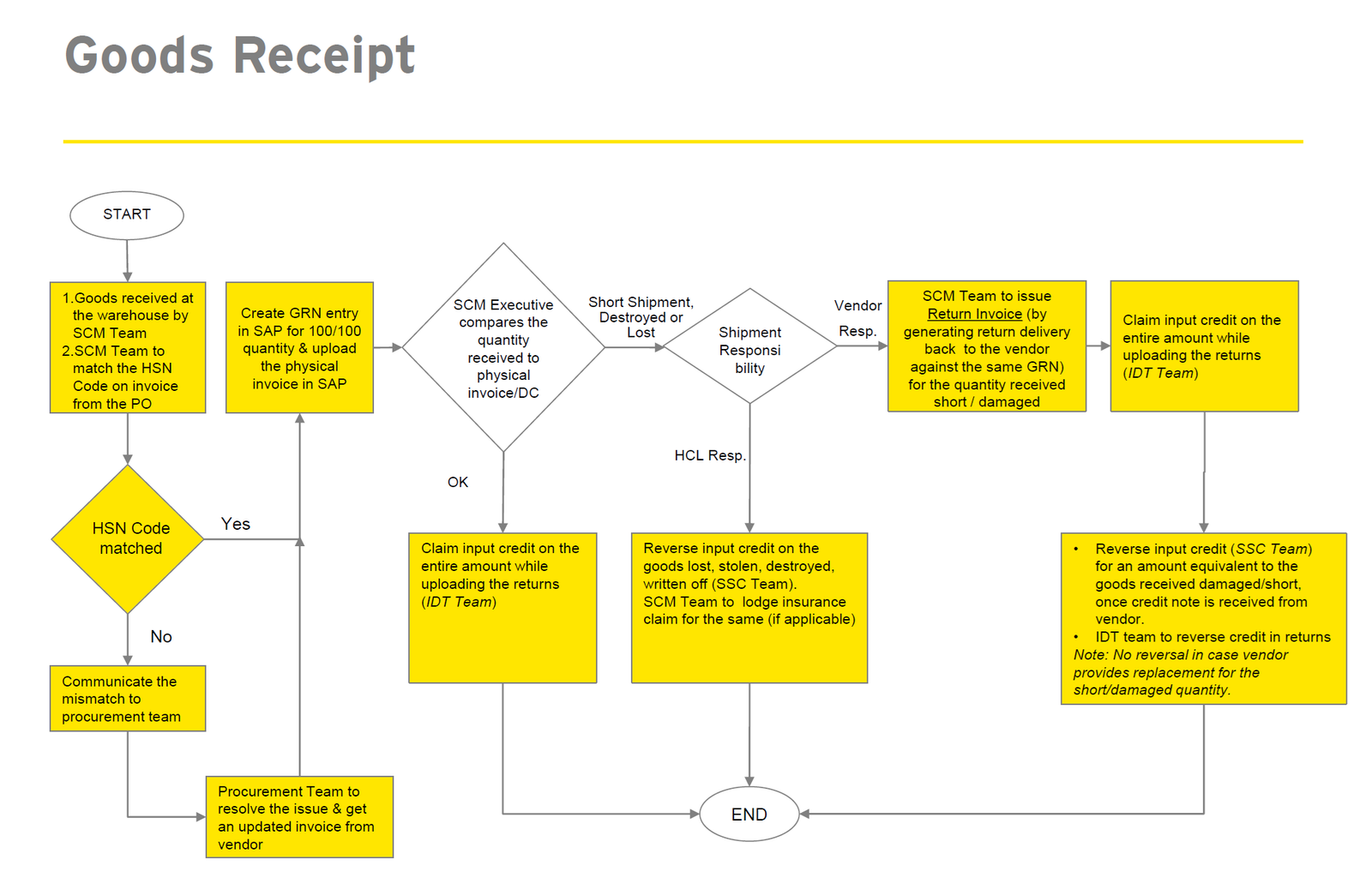

This flowchart outlines a sample “To-Be” Goods Receipt (aka GRN) process in SAP MM as part of the Procure-to-Pay (P2P) cycle, detailing the steps for verifying, processing, and managing the receipt of goods. Here’s a detailed breakdown of the process:

- Goods Receipt at Warehouse: The Supply Chain Management (SCM) team receives the goods at the warehouse.

- HSN Code Verification:

- The SCM team checks the HSN Code on the invoice against the Purchase Order (PO) to ensure accuracy.

- If HSN Code Matches: Proceed to the next step.

- If HSN Code Does Not Match: Communicate the mismatch to the procurement team, who will resolve the issue and obtain an updated invoice from the vendor.

- GRN Creation:

- Create a Goods Receipt Note (GRN) entry in SAP for the 100% quantity as noted and upload the physical invoice.

- Quantity Verification:

- An SCM executive compares the quantity received to the quantity listed on the physical invoice/document.

- If Quantity Matches (OK): Proceed to claim input credit.

- If There Is a Discrepancy (short shipment, goods destroyed or lost): Determine responsibility (Vendor or Owner) and proceed accordingly.

- Handling Discrepancies:

- Vendor Responsibility: The SCM team issues a return invoice by generating a return delivery back to the vendor for the quantity received that was short or damaged.

- HCL Responsibility: Reverse input credit on goods lost, stolen, or destroyed, and possibly lodge an insurance claim (if applicable).

- Credit Management:

- Claim Input Credit: The responsible team claims input credit on the entire amount while uploading the returns.

- Reverse Input Credit:

- If the goods are damaged/short, and the vendor provides a replacement, no reversal is necessary once a credit note is received.

- The SSC Team reverses the input credit for an equivalent amount to the goods received damaged/short once the vendor confirms the credit note.

- Completion: The process concludes with the final management of input credits and, if necessary, insurance claims, ensuring all goods received are accurately accounted for in SAP.

This flowchart provides a comprehensive guide for the goods receipt process, ensuring thorough verification and efficient handling of any discrepancies to maintain accurate inventory and financial records.