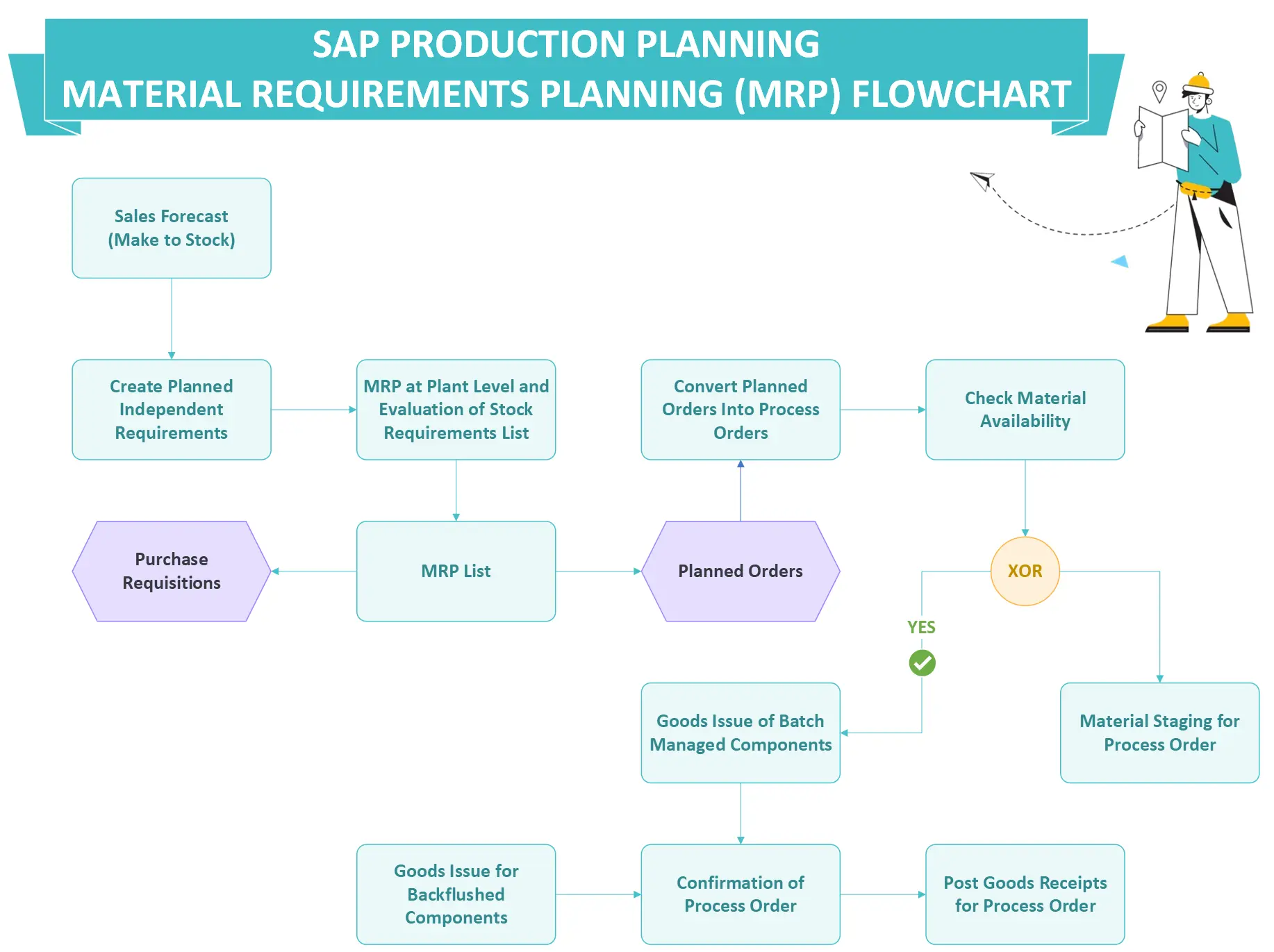

This flowchart maps the SAP Production Planning Material Requirements Planning (MRP) process within a manufacturing plant, particularly focusing on make-to-stock finished goods, their semi-finished precursors, and the raw materials required for production. Here is a step-by-step breakdown using the provided text to elaborate on the process:

- Sales Forecast (Make to Stock) + 📈: This is the starting point, which considers sales forecasts for finished products that are made to stock.

- Create Planned Independent Requirements + 📝: Based on the forecast and confirmed sales orders, planned independent requirements for finished goods are created.

- MRP at Plant Level and Evaluation of Stock Requirements List + 🏭: MRP runs at the plant level, considering both finished products and specific materials. It also includes a review of dependent requirements for semi-finished goods, raw materials, and intermediates.

- MRP List + 📋: The outcome of the MRP run is the MRP list, which details the net requirements for each material.

- Purchase Requisitions in SAP + 🛍️: If net requirements aren’t met by current stock or planned receipts, purchase requisitions for externally procured components are generated.

- Planned Orders + 📅: Similarly, planned orders for in-house production are created if existing supplies are insufficient.

- Convert Planned Orders Into Process Orders + 🔄: Planned orders are then converted into process orders, which are specific instructions for production.

- Check Material Availability + ✔️❌: A check is performed to ensure all materials needed for the process orders are available.

- Material Staging for Process Order + 📦: If materials are available, they are staged and ready for use in production.

- Goods Issue for Backflushed Components + ↩️: Components that are backflushed (automatically issued to a production order) have a goods issue posted.

- Goods Issue of Batch Managed Components + 📦: For components managed in batches, a separate goods issue is recorded.

- Confirmation of Process Order + ✅: The process order is confirmed once production is complete.

- Post Goods Receipts for Process Order + 🧾: Finally, goods receipts for the finished products of the process order are posted, completing the cycle.

The flowchart emphasizes the iterative nature of the MRP process in SAP, which balances the demand from sales forecasts and orders with the supply from in-house production and external procurement, ensuring that manufacturing can meet customer demand efficiently. Scheduling during the planning run calculates the start and finish dates for the planned orders, which is crucial for timely production and delivery.