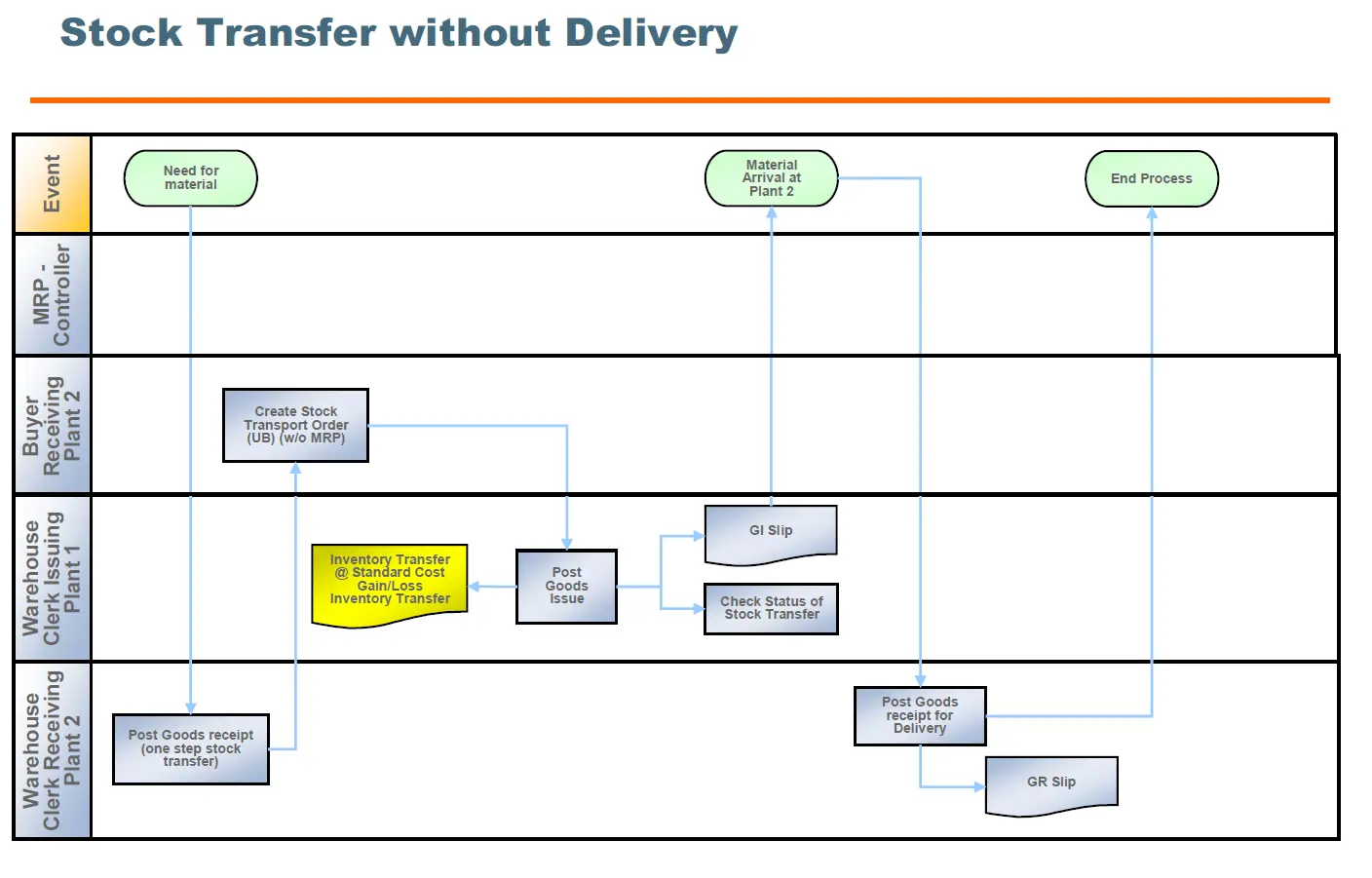

The flowchart presents the SAP process for internal stock transfer without the need for a delivery document within a single company code. This process is efficient for moving materials between plants, especially when they are geographically close, and there is no requirement to track stock in transit.

SAP Stock Transfer Process without Delivery:

- Need for Material 🛒: Identification of the requirement to move stock from one plant to another.

- Create Stock Transport Order (UB) (W/O MRP) 📝: A stock transport order is created by the buyer at the receiving plant to request materials from the issuing plant.

- Post Goods Issue 🚚: The issuing plant posts the goods issue, which decrements inventory and signifies the release of materials to the receiving plant.

- Inventory Transfer @ Standard Cost Gain/Loss Inventory Transfer 💲: The material is transferred in the system from the issuing plant to the receiving plant, with an immediate financial impact reflected by standard costing.

- Check Status of Stock Transfer 🔄: The process may include checking the status to ensure the stock transfer is accurately reflected in the system.

- GI Slip 🧾: A Goods Issue slip is generated, documenting the inventory changes at the issuing plant.

- Material Arrival at Plant 2 🏭: The material is recorded as having arrived at the receiving plant.

- Post Goods Receipt for Delivery ✅: The receiving plant completes the process by posting the goods receipt, which increases its inventory level accordingly.

- GR Slip 🧾: A Goods Receipt slip is created, finalizing the transaction and providing physical documentation for the receiving plant.

- End Process ➡️: The internal stock transfer is concluded with the material now available for use at the receiving plant.

This SAP flow, often facilitated by the Materials Management (MM) module, streamlines the internal transfer of goods between plants, enhancing operational efficiency by eliminating unnecessary steps and documentation, especially when the immediacy of the transfer is crucial.