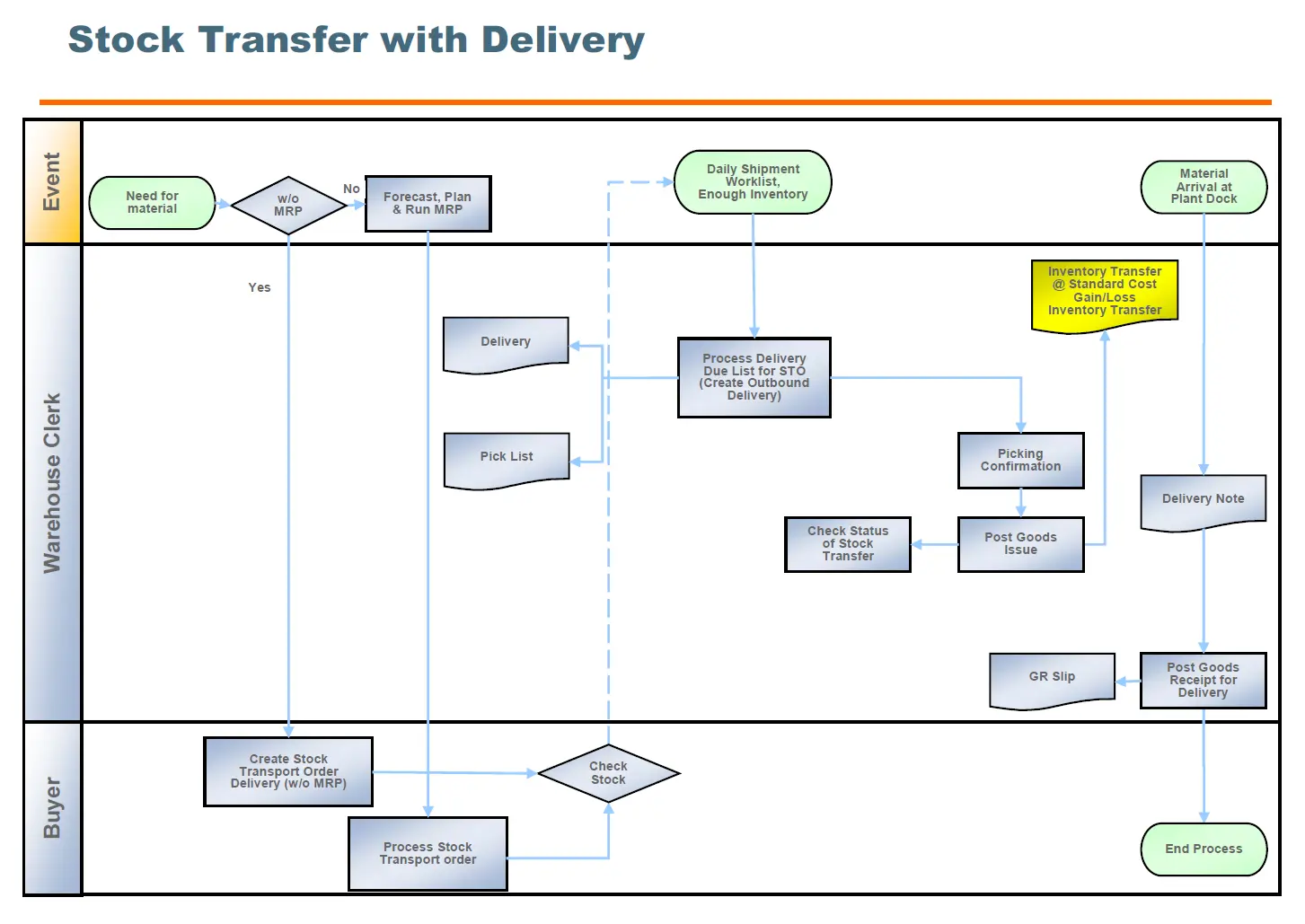

The flowchart delineates the SAP stock transfer process, a mechanism used to move inventory from one plant to another within the same company code, bypassing the need for master data beyond the material master. It encompasses the generation of a stock transfer requisition, creation of a stock transfer order, and the final goods receipt at the destination plant.

SAP Stock Transfer Process:

- Need for Material 🛒: The process starts when there is a requirement to transfer material between plants.

- Create Stock Transport Order Delivery (W/O MRP) 📝: If there’s an existing need without an MRP run, a stock transport order is directly created.

- Forecast, Plan & Run MRP 🔄 (If Required): In case there’s no immediate need, MRP is planned and run to forecast material requirements.

- Delivery 📦: The delivering plant creates a delivery document for the transfer of stock.

- Pick List 📃: A pick list is generated from the delivery document, detailing the items to be picked from inventory.

- Process Stock Transport Order 🔄: The buyer processes the stock transport order after verifying the requisition’s accuracy.

- Check Stock ✅: The warehouse clerk checks the stock against the pick list.

- Process Delivery Due List for STO (Create Outbound Delivery) 📋: The delivery due list is processed to create an outbound delivery for the stock transfer.

- Check Status of Stock Transfer 🔄: The status of the stock transfer is monitored to ensure the process is on track.

- Picking Confirmation ✅: The warehouse clerk confirms the quantities picked for transfer.

- Post Goods Issue 🚚: After picking confirmation, the goods are issued from the delivering plant, and the shipping documentation is prepared.

- Inventory Transfer @ Standard Cost Gain/Loss Inventory Transfer 💲: The inventory is received and updated at the standard cost, recording any gains or losses during the transfer.

- Delivery Note 📝: The delivery note details the specifics of the transfer and accompanies the goods.

- Post Goods Receipt for Delivery ✅: The final step at the receiving plant is posting the goods receipt, which concludes the process.

- GR Slip 🧾: A goods receipt slip is generated, completing the receiving process.

This SAP Materials Management (MM) module process streamlines internal material movement, providing a controlled and documented transfer system that impacts inventory levels across plants without the need for external procurement processes.