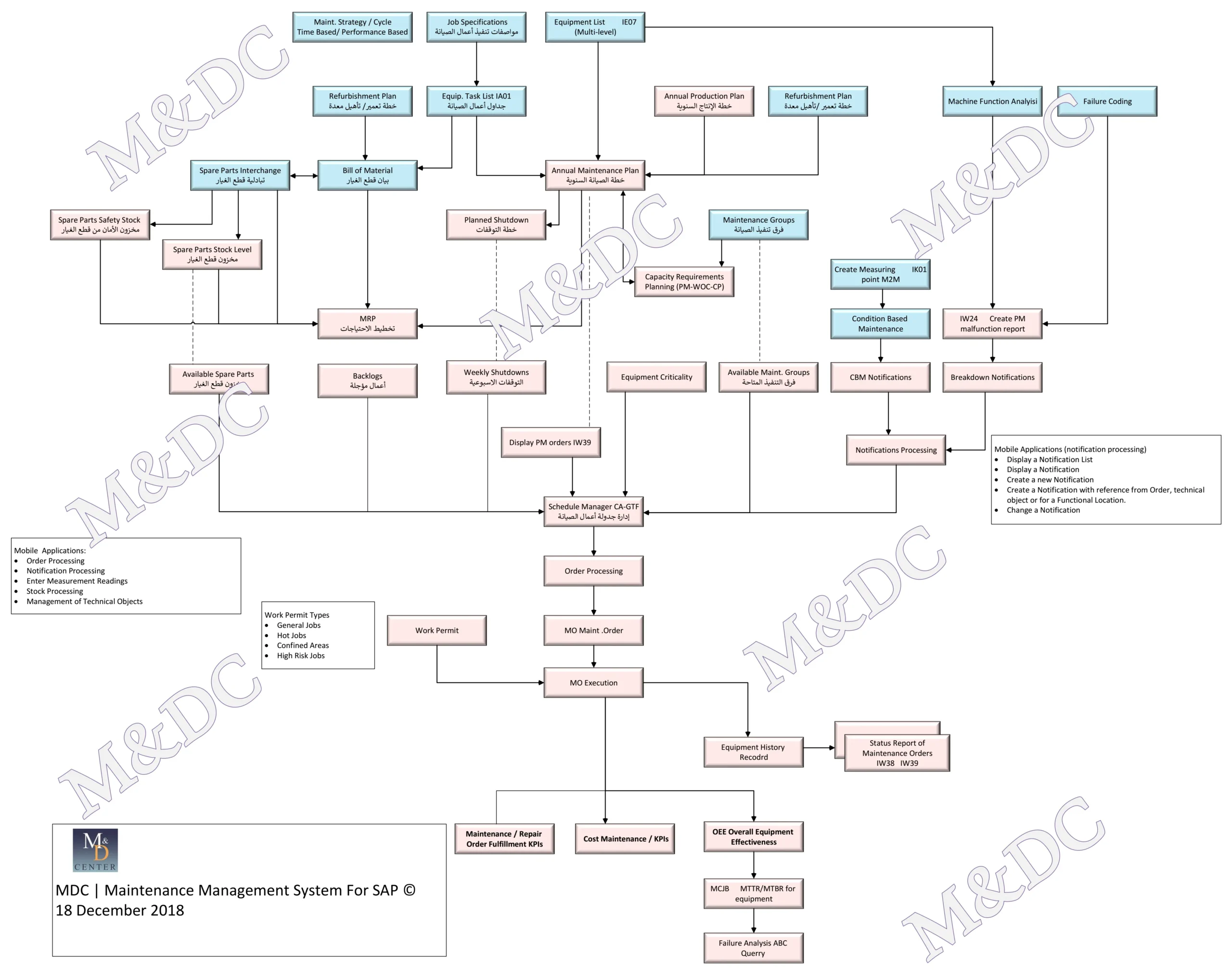

This workflow diagram provides a clear visual roadmap to streamline Plant Maintenance (PM) process in SAP ERP, helping to keep equipment running smoothly and avoid costly breakdowns.

From Planning to Performance:

The chart starts with the essential building blocks: defining your Maintenance Strategy, creating Job Specifications, and compiling your Equipment List. This initial planning lays the groundwork for effective PM. It moves through creating crucial documents like Refurbishment Plans, Equipment Task Lists, and your Annual Production Plan.

Managing Spares and Schedules:

Efficient spare parts management is key. The flowchart highlights steps for Spare Parts Interchange, managing your Bill of Materials (BOM) and maintaining optimal Spare Parts Stock Levels. This ensures you have the right parts when you need them.

On the scheduling side, the chart details how to move from Planned Shutdowns and Weekly Shutdowns into generating and displaying PM Orders. It even factors in Condition Based Maintenance (CBM), triggered by measuring points, allowing for proactive interventions.

Execution and Analysis:

The lower part of the flowchart focuses on the execution of maintenance. It includes Work Permit processes and the creation and execution of Maintenance Orders. Crucially, it emphasizes tracking Equipment History and generating Status Reports on maintenance orders.

Finally, the flowchart brings it all together by focusing on performance metrics like Maintenance/Repair Order Fulfillment KPIs and Overall Equipment Effectiveness (OEE). This data-driven approach allows you to continuously improve your PM strategy and conduct Failure Analysis for long-term equipment reliability.

SAP PM Process In a Nutshell:

This flowchart provides a fantastic visual guide to a comprehensive Preventive Maintenance system. By following these steps, from initial planning and spare parts management to execution and performance analysis, you can ensure your equipment stays in top condition, minimizing downtime and maximizing efficiency. Take a look and see how you can apply this structured approach to your own maintenance processes!