Ever feel lost in the sea of tables within SAP Production Planning (PP)? You’re not alone! Understanding the relationships between key tables is crucial for troubleshooting, reporting, and gaining deeper insights into your production processes.

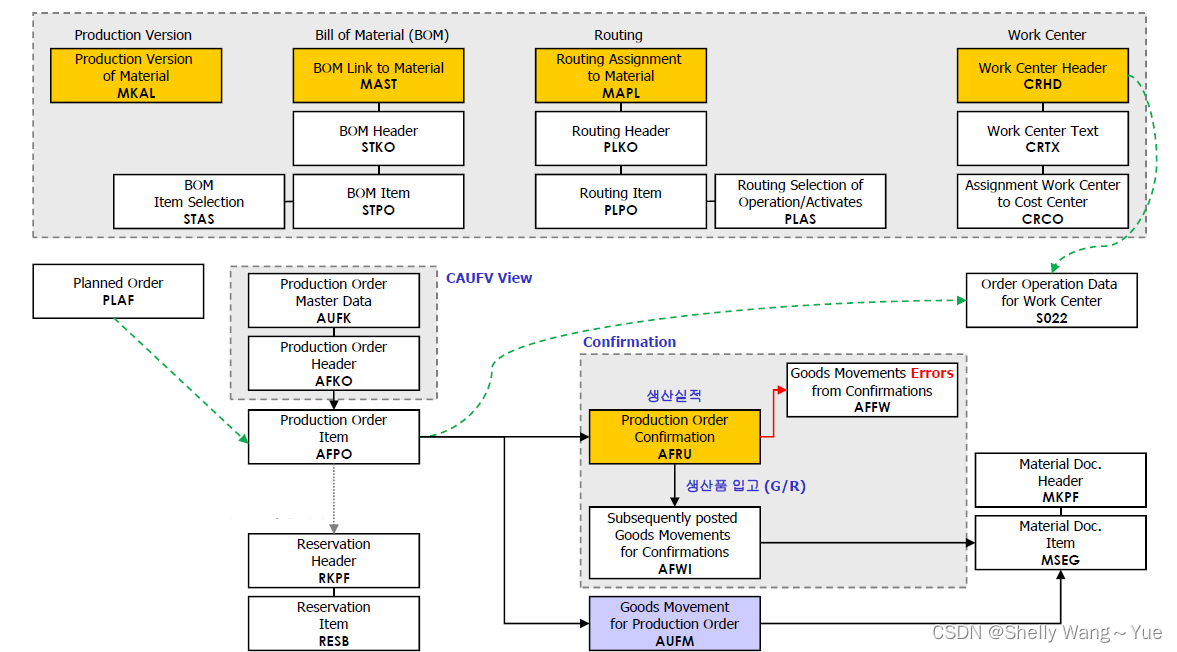

This helpful diagram visualizes some of the most important SAP PP tables. Think of this as your quick visual cheat sheet to navigate the PP data landscape. This diagram lays out the tables in a logical flow, mirroring the typical production planning process in SAP. Below is a high-level overview of the main tables you’ll encounter in a standard production flow.

1. Master Data Foundations:

- Production Version (MKAL): This is where you define different ways to produce a material. Think of it as different “recipes” for the same product.

- Bill of Material (BOM) Tables (MAST, STKO, STPO, STAS): These tables together define the BOM – the list of components needed to make your product. From the link between material and BOM (MAST) to the header (STKO), items (STPO), and item selection (STAS), it’s all about defining what goes into your product.

- Routing Tables (MAPL, PLKO, PLPO, PLAS): Routing outlines how to make your product. These tables detail the sequence of operations, work centers involved, and more. From assignment to material (MAPL), header (PLKO), items (PLPO) and operation selection (PLAS), routing tables define the production steps.

- Work Center Tables (CRHD, CRTX, CRCO): Work centers are the machines or locations where production happens. These tables store header data (CRHD), text descriptions (CRTX), and cost center assignments (CRCO) for your work centers.

2. Planning and Execution:

- Planned Order (PLAF): This is the starting point for production planning. Planned orders are system proposals for production quantities based on demand.

- Production Order Tables (AUFK, AFKO, AFPO): When you convert a planned order, you create a production order. These tables hold the core data for production orders: Master data (AUFK), Header data (AFKO), and Item details (AFPO).

3. Confirmation and Goods Movements:

- Confirmation Tables (AFRU, AFFW, AFWI): As production progresses, confirmations are recorded. AFRU holds the actual confirmation data, while AFFW and AFWI handle goods movement errors and subsequent postings related to confirmations.

- Goods Movement Tables (AUFM, MKPF, MSEG): Goods movements are the physical movement of materials (like issuing raw materials to production or receiving finished goods). AUFM is for goods movements related to production orders, while MKPF (header) and MSEG (item) are general material document tables.

4. Key Linkages:

You will notice there are some relationships between the tables. For example, a Planned Order (PLAF) gets converted into a Production Order (AUFK, AFKO, AFPO). Production Order Confirmation (AFRU) then triggers Goods Movements (AUFM).