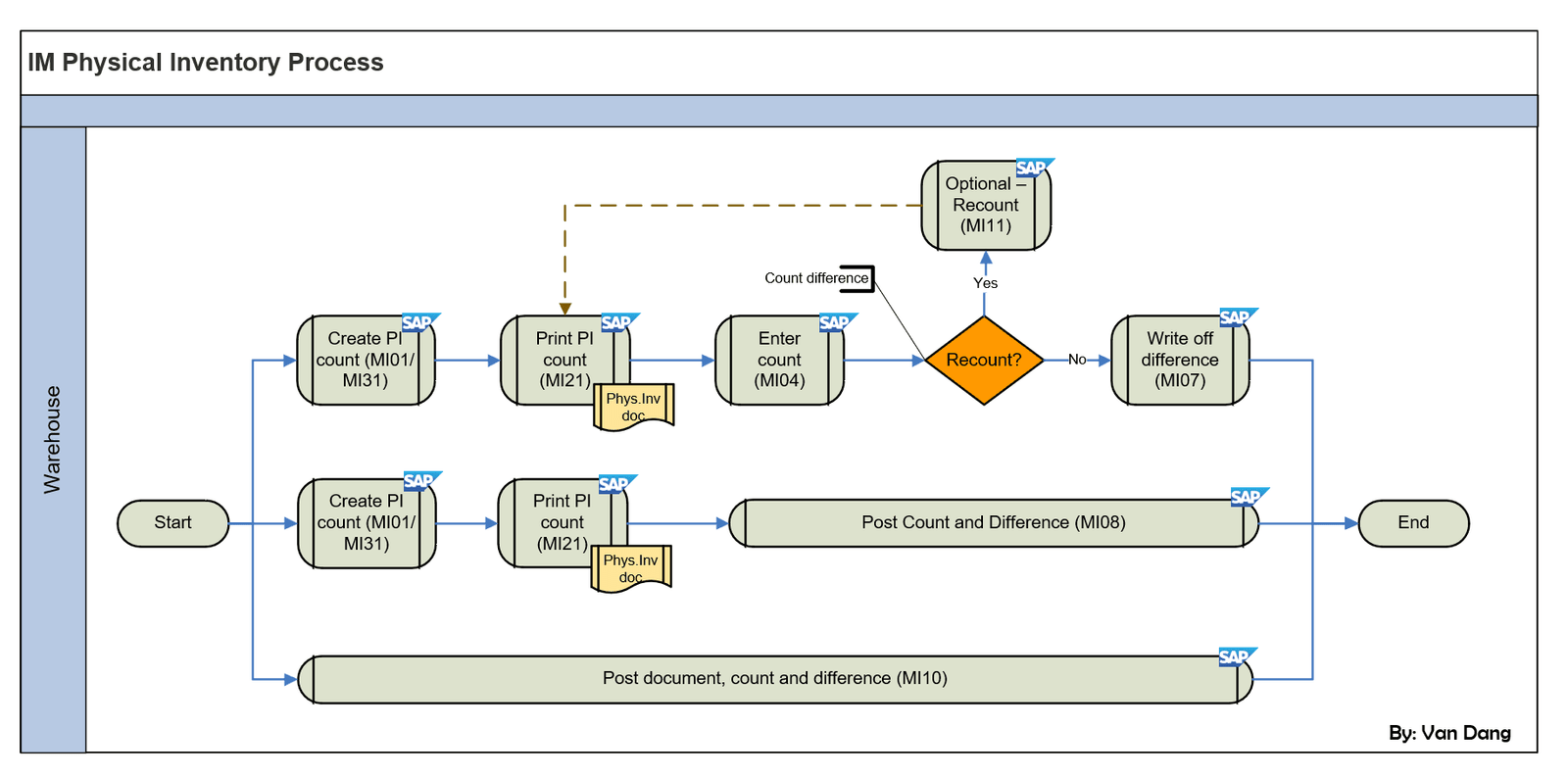

The SAP Inventory Management (IM) Physical Inventory Process is a critical component for maintaining accurate inventory records within a warehouse setting. This process ensures that the physical stock matches the system records, facilitating effective inventory control and operational decision-making. The flowchart, created by Dang_Bao_Van, provides a visual representation of the various steps, transaction codes, and decision points involved. Below is a detailed breakdown of the flowchart.

1. General Overview

The flowchart outlines the steps required to conduct a physical inventory count using SAP IM. It encompasses the creation of Physical Inventory (PI) documents, the actual counting of stock, handling discrepancies, and utilizing various SAP transaction codes to manage these activities. The primary SAP transactions involved include:

- MI01/MI31: Creation of PI documents.

- MI21: Printing PI documents.

- MI04: Entering count results.

- MI11: Recounting if necessary.

- MI07: Writing off differences.

- MI08: Posting count and differences simultaneously.

- MI10: Comprehensive transaction for creating documents, entering counts, and posting differences.

- MI20: Reporting tool for viewing differences before clearing.

- MI24: Generating inventory lists.

2. Detailed Flow Diagram Breakdown

Step 1: Create PI Document (MI01/MI31)

- MI01 (Create PI Document): This transaction code is used to manually create a PI document for specific materials. Users enter material numbers individually, along with relevant details such as batch information if applicable.

- MI31 (Create PI Document with Batch Input): This method allows for the creation of multiple PI documents simultaneously by selecting materials based on predefined criteria such as plant, storage location, or material group. This batch input process streamlines the documentation phase, especially for warehouses with extensive inventories.

Regardless of the method chosen, the PI document is created and activated, serving as the official record for the physical inventory count.

Step 2: Print PI Document (MI21)

- MI21 (Print PI Document): This step is optional but recommended for maintaining a physical record or for verification purposes. Printing the PI document provides a tangible inventory list that can be used during the physical counting process.

Step 3: Enter Count (MI04)

- MI04 (Enter Count Results): After conducting the physical count, the results are manually entered into the system using this transaction code. Each line item within the PI document is updated with the corresponding counted quantity.

- Post-Entry Actions: Once the count is entered, users can either save the results or make adjustments as necessary. If discrepancies are identified, users may need to trigger a recount using MI11 or modify the count using MI05.

Step 4: Decision Point – Recount?

At this juncture, a decision is made based on the accuracy of the entered count:

- Yes: If significant discrepancies are detected, a recount is initiated using MI11. This step involves re-evaluating the physical stock to ensure accuracy.

- No: If the count is deemed accurate or discrepancies are within acceptable limits, the process proceeds to write off any differences.

Step 5: Write Off Difference (MI07)

- MI07 (Write Off Difference): This transaction is used to post any differences between the counted quantities and the system quantities.

- Movement Types:

- 701: Used for stock increases, reflecting an addition to the inventory.

- 702: Used for stock decreases, indicating a reduction in inventory.

Executing MI07 generates a material document that records these adjustments, ensuring that inventory records are updated accurately.

Step 6: Alternative Comprehensive Options

To enhance efficiency, SAP offers alternative transaction codes that combine multiple steps:

- MI08 (Post Count and Difference): This transaction allows users to enter the count and simultaneously post any discrepancies in one step, streamlining the process by reducing the number of transactions required.

- MI10 (Post Document, Count, and Difference): This is a more powerful transaction that enables users to create the PI document, enter the count, and post discrepancies all within a single transaction. MI10 is particularly beneficial for high-volume warehouses seeking to minimize processing time.

Step 7: Informative Reporting

To monitor and analyze inventory discrepancies, SAP provides reporting tools:

- MI20 (See Difference Before Clear Off): This report offers a real-time overview of all count differences, allowing users to review discrepancies before any adjustments are made. It facilitates informed decision-making regarding which differences require action.

- MI24 (Inventory List): This report generates a comprehensive list of all physical inventory documents, displaying their statuses. Users can navigate from this list to other functions, such as posting differences or modifying counts.

📚Useful resources for SAP MM-IM Physical Inventory Process:

- Physical Inventory in SAP MM: Presentation Document to Understanding the Process and Key Steps (PDF File)

- Physical Inventory Configuration Guide in SAP S/4HANA MM (PDF File)

- SAP MM Physical Inventory Process Manual: Document Create, Count and Difference Posting (PDF File)

- SAP MM Physical Inventory Processes (Video Tutorial)