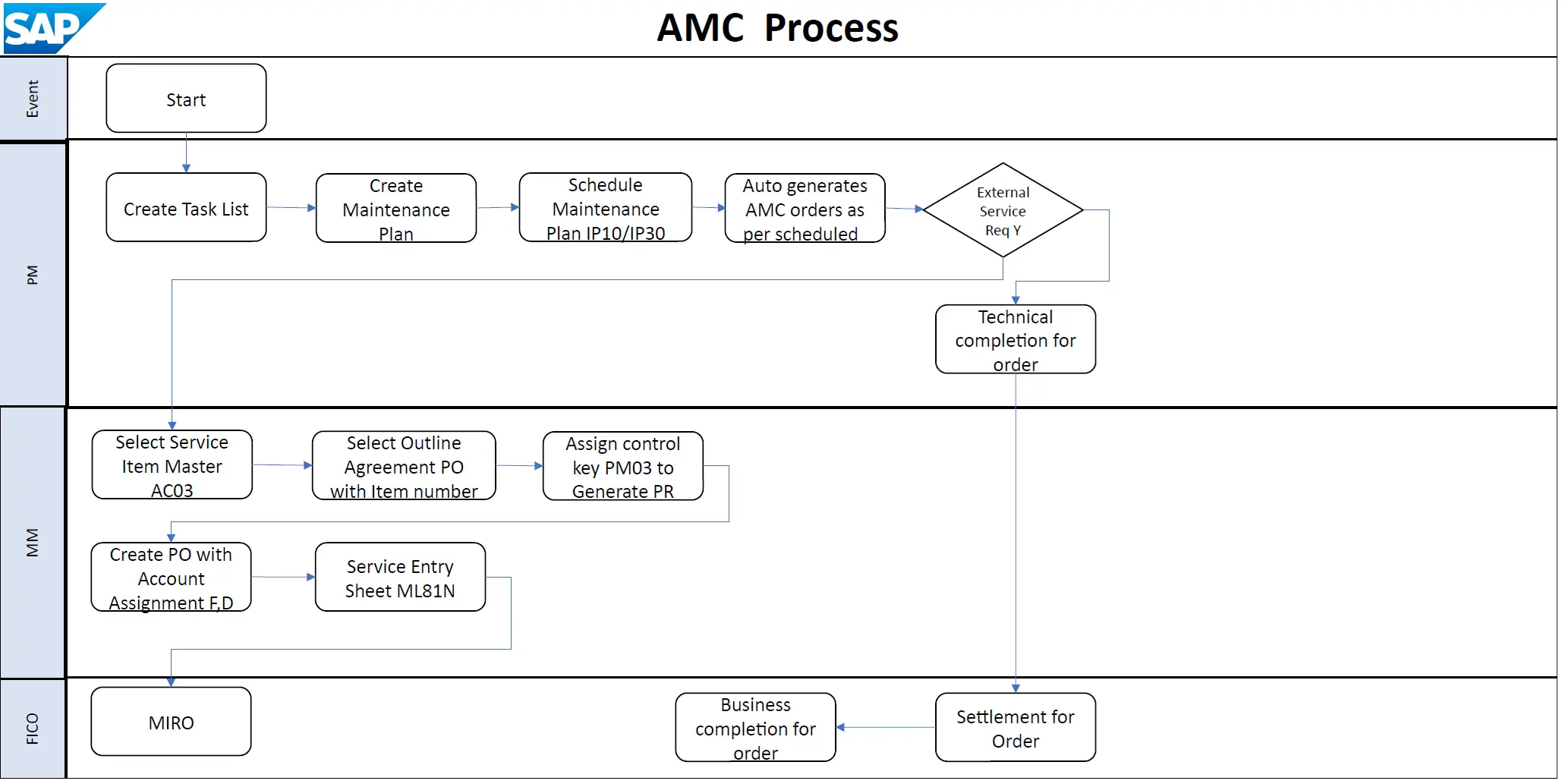

The flowchart illustrates the Annual Maintenance Contract (AMC) Process within the SAP system, integrating modules such as Plant Maintenance (PM), Materials Management (MM), and Financial Accounting & Controlling (FICO). AMC stands for Annual Maintenance Contract. In SAP, it’s a process used to manage and track regular maintenance activities for equipment or assets. This process ensures that assets are kept in optimal working condition, reducing downtime and costs.

Below is a detailed breakdown of the process shown in flowchart image:

🛠️ Plant Maintenance (PM) Activities

- Create Task List (Transaction: IA05 or IA06): A task list for AMC activities is created, defining a sequence of individual maintenance activities which are repeatedly performed. This is used to standardize repetitive work processes to plan them more effectively and save time when creating maintenance orders.

- Create Maintenance Plan (Transaction: IP41 or IP42): A maintenance plan is established to schedule regular AMC activities. The maintenance plan in this step merges the specific strategies, items, measuring points, task lists to generate recurring maintenance schedule. Maintenance plans can be displayed as list using IP15 – IP16 tcodes

- Schedule Maintenance Plan (Transaction: IP10 or IP30): The maintenance plan is scheduled and activated in the system in order to generate call objects .

- Auto Generates AMC Orders as per Scheduled: AMC orders are automatically generated based on the defined schedule.

- External Service Required? (Yes/No): A decision point to determine if external services are needed for the AMC.

- Technical Completion for Order (Transaction: IW32): Once all predefined services in PO are consumed, then the AMC order is marked as technically complete after service execution.

📦 Materials Management (MM) Actions

- Select Service Item Master AC03: The appropriate service item is selected from the master data.

- Select Outline Agreement PO with Item Number: An outline agreement purchase order is selected, referencing the specific item number.

- Assign Control Key PM03 to Generate PR: The control key PM03 is assigned to generate a purchase requisition for the service.

- Create PO with Account Assignment F,D: A purchase order is created with the appropriate account assignment.

- Service Entry Sheet ML81N (Transaction: ML81N): A service entry sheet, which is logged for the purpose of payment to vendor with MIRO tcode, is created to record the services provided under the AMC.

💰 Finance/Controlling (FICO) Steps

- MIRO (Transaction: MIRO): The invoice verification process is performed for the AMC services.

- Settlement for Order (Transaction: KO88): Order settlement & business closure to be done by finance department. Here cost of order will be settled to cost center and order cost becomes zero

🔗 Key Integration Points:

- PM to MM: AMC requirements trigger service procurement processes.

- MM to FICO: Service entries and purchases initiate financial transactions.

- PM to FICO: Completed AMC orders are settled in the controlling module.

This AMC process in SAP demonstrates the systematic approach to managing long-term maintenance contracts, ensuring regular service execution, proper documentation, and cost control. It showcases the integration between different SAP modules to streamline the entire AMC lifecycle from planning to financial settlement.