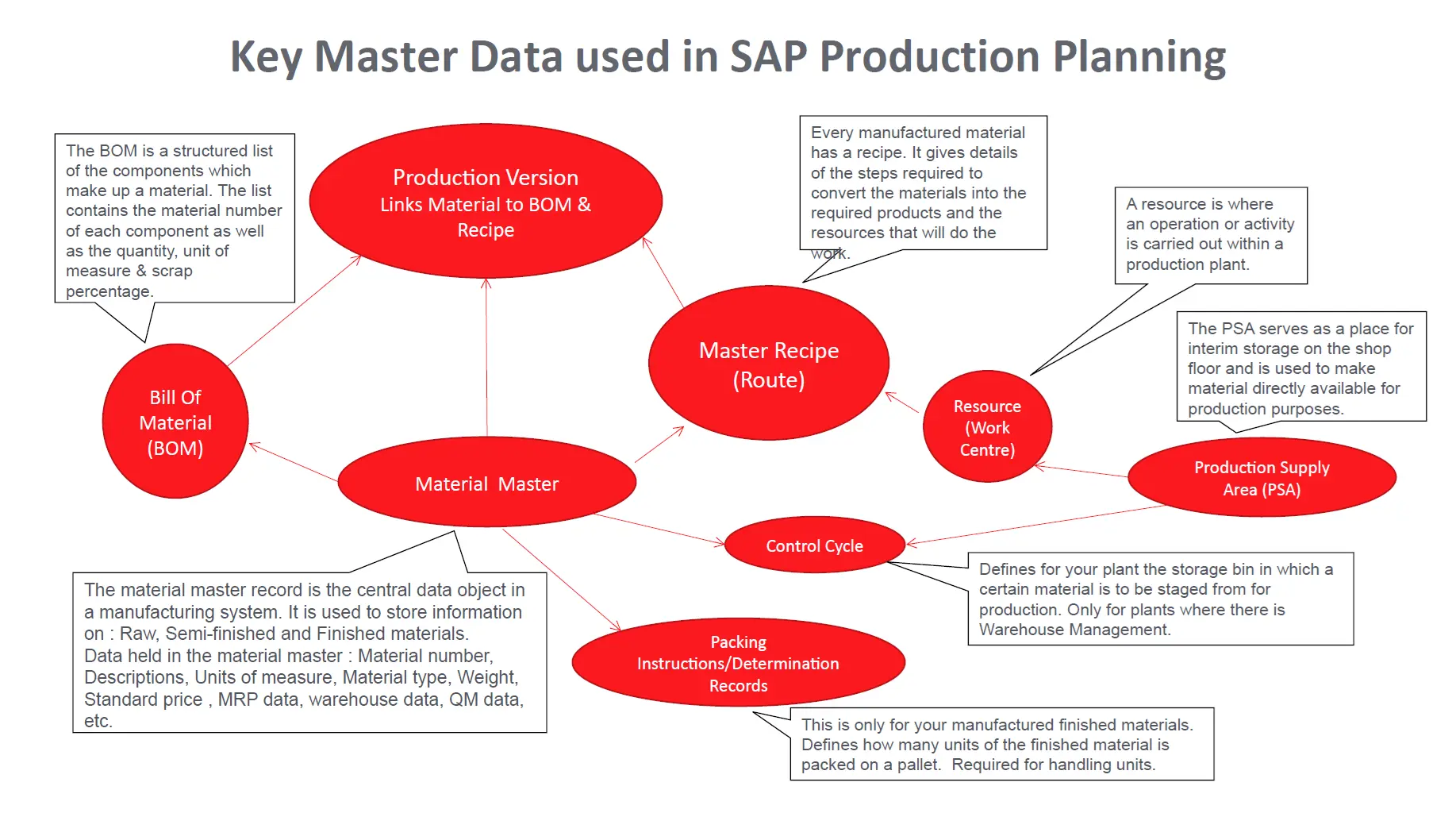

SAP’s Production Planning module relies on several key master data elements to streamline operations as shown in the diagram. Let’s break down these essential components and how they interconnect in the system:

- Material Master: At the heart of SAP’s production planning lies the Material Master. This central data object stores critical information about raw materials, semi-finished goods, and finished products. It includes details such as material numbers, descriptions, units of measure, material types, weights, standard prices, MRP data, warehouse data, and quality management information.

- Bill of Material (BOM): The BOM is a structured list detailing the components that make up a material. It specifies the material number, quantity, unit of measure, and scrap percentage for each component. This forms the foundation for understanding product composition and resource requirements.

- Production Version: This element links the material to its corresponding BOM and recipe. It’s the bridge that connects what we’re making to how we’re making it.

- Master Recipe (Route): Every manufactured material has a recipe, which outlines the steps required to convert raw materials into finished products. It also specifies the resources needed for each step, ensuring a clear production roadmap.

- Resource (Work Center): A resource represents where an operation or activity is carried out within a production plant. This could be a machine, a group of machines, or a specific work area.

- Production Supply Area (PSA): The PSA serves as an interim storage location on the shop floor, making materials readily available for production purposes. This helps optimize material flow and reduces production delays.

- Control Cycle: This element defines the storage bin in your plant where specific materials are staged for production. It’s particularly relevant for plants utilizing Warehouse Management systems.

- Packing Instructions/Determination Records: Applicable only to manufactured finished materials, these records define how many units of the finished product are packed on a pallet. This information is crucial for handling units efficiently.

Related content from other SAP resources: