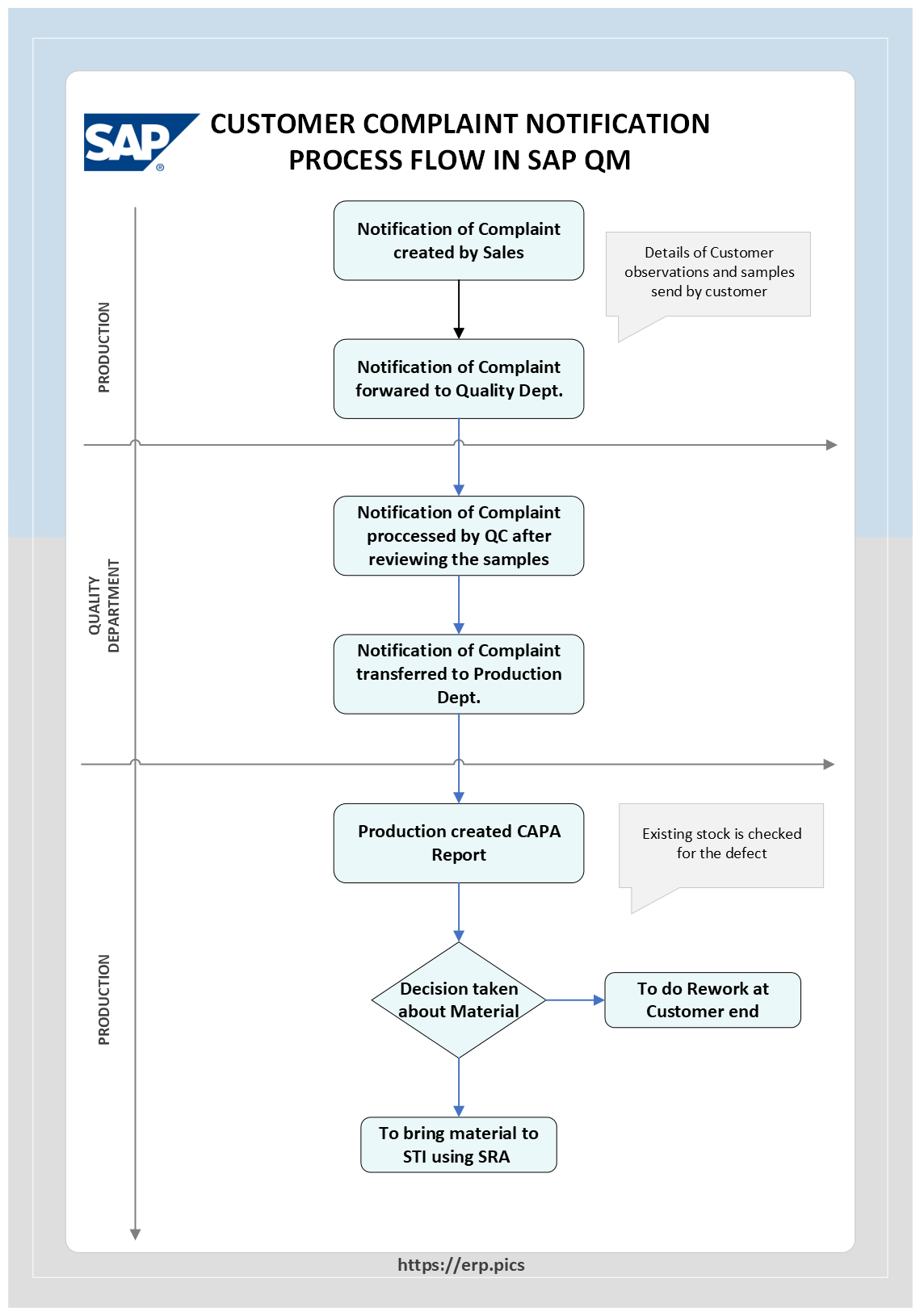

This flowchart details the steps for handling customer complaints in the SAP Quality Management (QM) module. The process ensures that all customer issues are addressed, analyzed, and resolved systematically.

- Notification of Complaint Created by Sales 📧: Complaints received through the Sales/Customer Support Department are logged. Customers may directly inform the factory QA head or send emails detailing their observations and samples.

- Notification of Complaint Forwarded to Quality Dept. 📄: The sales department forwards the complaint notification to the quality department for further processing.

- Notification of Complaint Processed by QC 🧪: The Quality Control (QC) team reviews the samples and processes the complaint. Complaints are categorized as either technical or logistics-related.

- Notification of Complaint Transferred to Production Dept. 📦: The processed complaint is then transferred to the production department for detailed analysis and resolution.

- Production Created CAPA Report 📝: The production team creates a Corrective and Preventive Action (CAPA) report. Existing stock is checked for defects as part of the investigation.

- Decision Taken About Material 🏭: A decision is made regarding the material:

- Bring Material to Stock Using SRA 🔄

- If rework is possible, the material is returned to stock using a Sales Return Authorization (SRA) and reworked accordingly.

- To Do Rework at Customer End 🔧

- If rework is to be done at the customer’s end, the necessary actions are taken.

- Bring Material to Stock Using SRA 🔄

- Additional Steps 🚀

- Sales Return Invoice 📜: A sales return invoice is generated, and the material is taken under quality stock.

- QA Analysis 🔍: Complaints are handed over to the relevant team for analysis. Production personnel analyze defects based on customer specifications and take immediate action to prevent future occurrences.

- Customer Feedback 📣: Feedback is provided to the customer in their specified format, detailing the root cause analysis and corrective actions. This is managed by the production department and approved by QA.

- Record Keeping 📚: All customer complaints are registered, and notifications are saved as lifetime records for future reference.

- Corrective Actions ✅: After analyzing the root cause, corrective actions are initiated and attached to the notification. This ensures a systematic approach to resolving issues and improving processes.

This process flow ensures that customer complaints are systematically managed, analyzed, and resolved, with feedback provided to the customer and records maintained for future reference.