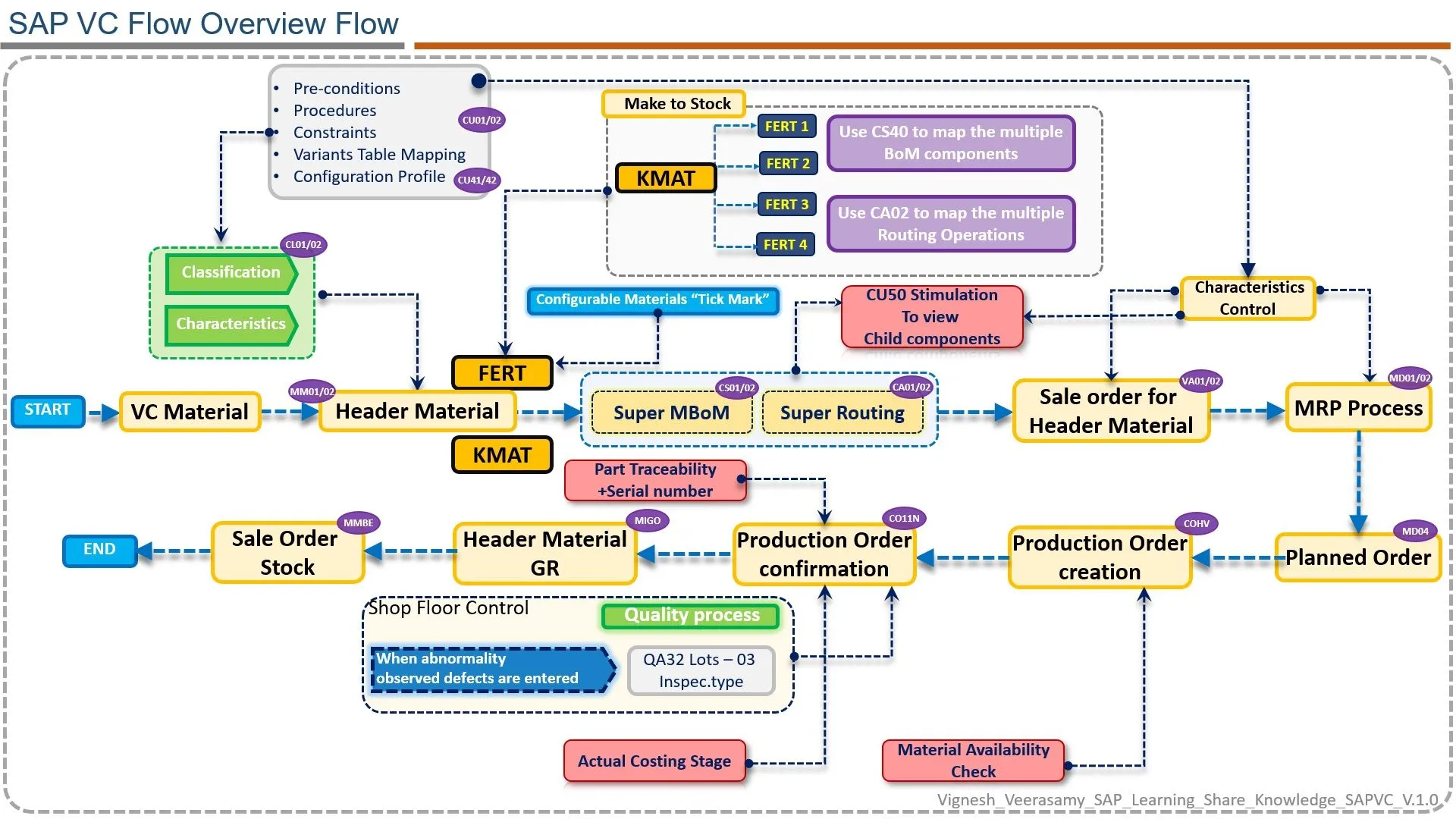

The picture, illustrated by Vignesh Veerasamy, outlines the flow of processes within SAP Variant Configuration (VC). Here’s a step-by-step explanation:

- Start with VC Material: It begins with a Variant Configurable Material (VC Material), which is a type of material in SAP that can be customized with various options and features.

- Classification: The material is classified with certain characteristics. Characteristics are attributes that define the variants of the material, and these are organized under classes.

- Header Material: The classified material is used to create a Header Material marked with KMAT, indicating that it is configurable.

- Make to Stock Process: Various FERT (Finished Products) materials are created from the Header Material for the make-to-stock process. Here, CS40 is used to map multiple Bill of Materials (BoM) components, and CA02 for mapping multiple Routing Operations.

- Super BOM and Routing: The Header Material is also associated with a Super Bill of Material (MBOM) and Super Routing, which are templates for producing configurable materials.

- Part Traceability: At this stage, part traceability is maintained, which may include serial numbers to track individual items.

- Sale Order for Header Material: A sales order is created for the Header Material, which triggers the Material Requirements Planning (MRP) process.

- MRP Process: The MRP process helps to plan and manage materials required for production. It ensures materials are available for production and product delivery to customers.

- Production Order Creation: Based on the MRP, a production order is created.

- Material Availability Check: The system checks if all materials are available for the production order.

- Production Order Confirmation: Once the material availability is confirmed, the production order can be executed, and this is followed by confirmation of the production order.

- Goods Receipt for Header Material: After production is completed, Goods Receipt (GR) for the Header Material is posted.

- Quality Process: The quality of the produced goods is checked, with QA32 being used to inspect the lot.

- Shop Floor Control: During the production process, if any abnormalities or defects are found, they are entered into the system for shop floor control.

- Actual Costing Stage: The actual costs incurred during production are recorded, which is essential for cost accounting and profitability analysis.

- End with Sale Order Stock: The process ends with the finished goods being available for sale, updating the stock levels accordingly.

Throughout the process, there are various points where characteristics are controlled and confirmed, ensuring that the product meets the configurable specifications requested by the customer. The flowchart is a high-level representation of the Variant Configuration process, showing how the sales, production, and quality stages are interconnected within the SAP system.

Hello,

Do you flow chart for MTO scenario with Variant Configurator, please share