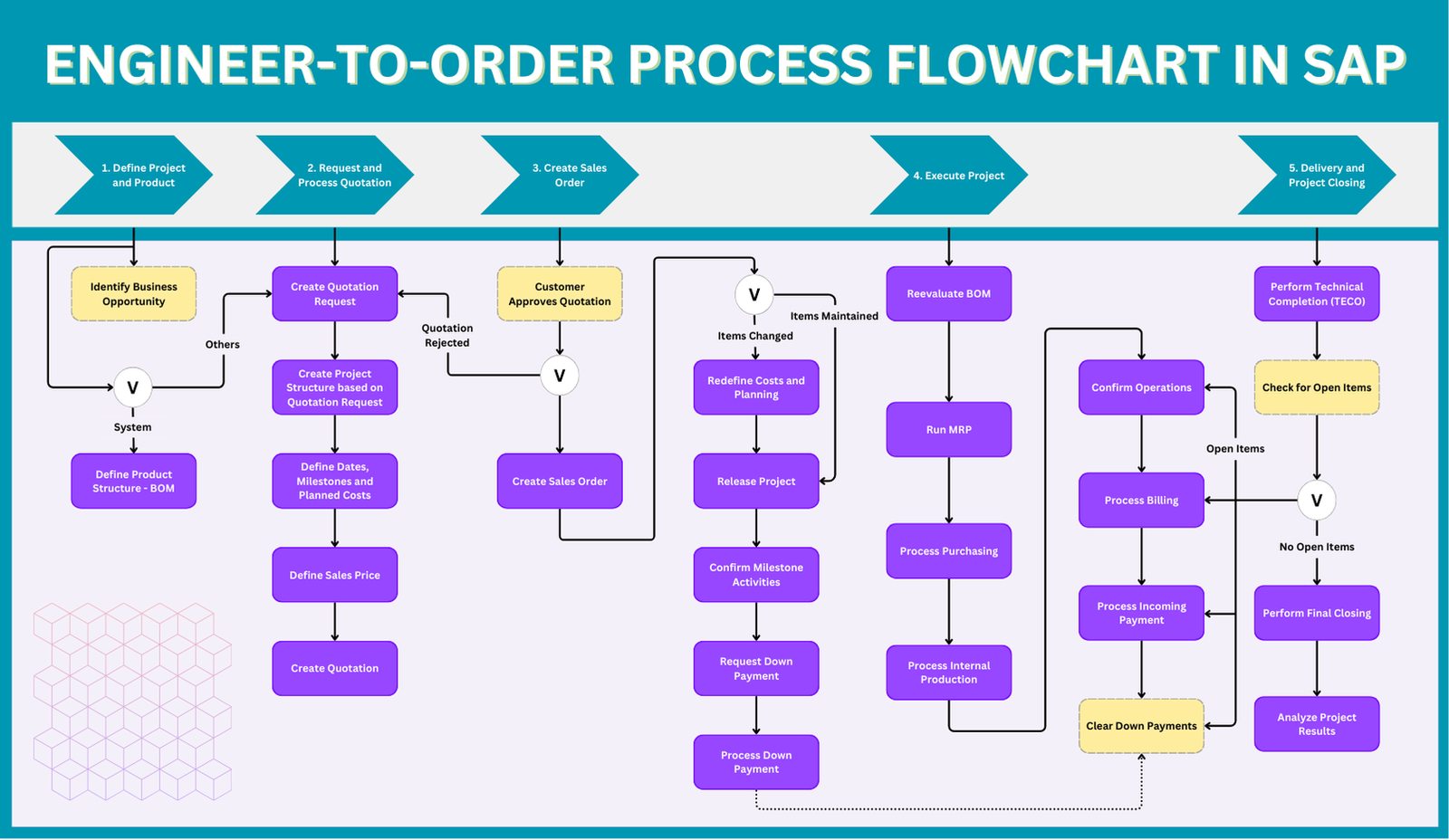

This flowchart illustrates the standard Engineer-to-Order (ETO) process within an SAP ERP system, outlining the key stages from initial project definition and quotation to final delivery and project closure. It provides a visual representation of the sequential steps and decision points involved in managing ETO projects within SAP, emphasizing the integration between different SAP modules like SD, PP, MM and PS.

Engineer-to-Order (ETO) Definition in SAP: In the context of manufacturing models, Engineer-to-Order (ETO) refers to a production approach where products are specifically designed, engineered, and manufactured to meet unique customer requirements and specifications. This model is characterized by complex end products, a significant degree of new design for each order (at least 20%), project-based manufacturing, and a strong emphasis on customer service and integrated product & process design with stringent documentation standards.

Process Descriptions (Main Stages):

1. Define Project and Product: This initial phase focuses on establishing the foundation for the ETO project within SAP. It starts with identifying a business opportunity and progresses through creating a quotation request. Crucially, it involves defining the project structure, often based on standard templates, and structuring the product using a super Bill of Materials (BOM) to facilitate configuration. Key activities include defining planned dates, milestones, and costs, ultimately leading to the creation of a customer quotation with a defined sales price.

2. Request and Process Quotation: This stage encompasses the activities surrounding the customer quotation. It begins with creating a quotation request within SAP’s Sales and Distribution (SD) module. Costing is determined based on the super BOM, incorporating indirect costs. The SD module is also utilized for pricing, factoring in elements like taxes and profit margins. This phase includes a loop for quotation approval by the customer; if rejected, the process may loop back or terminate, while approval proceeds to the next stage.

3. Create Sales Order: Upon customer quotation approval, the process moves to sales order creation. This stage marks the formal commencement of the ETO project execution after a successful sale. While initial planning happens during quotation, some material specifications may be refined post-sale, potentially requiring adjustments to the BOM. Project release within SAP triggers Material Requirements Planning (MRP), which in turn generates planned orders for semi-finished goods manufacturing, initiating procurement and production activities.

4. Execute Project: This is the core execution phase where the project plan is put into action. It starts with refining the project schedule and finalizing product structures post sales order creation. MRP execution is central, creating planned orders that are then converted into production orders. Production orders are processed, and shop floor activities including confirmations and material consumption are managed within SAP’s Production Planning (PP) module. Quality Management (QM) is integrated for semi-finished goods inspection, and project progress is monitored throughout this stage.

5. Delivery and Project Closing: The final phase focuses on completing the project and financial settlement. Once production is complete and goods are ready, the delivery process is initiated. Billing and invoicing are processed, and any down payments are cleared. Technical Completion (TECO) is executed in SAP to signify project completion from an operational perspective. Finally, after ensuring no pending items remain, the project undergoes final closing, and a post-project analysis of the project results is conducted.