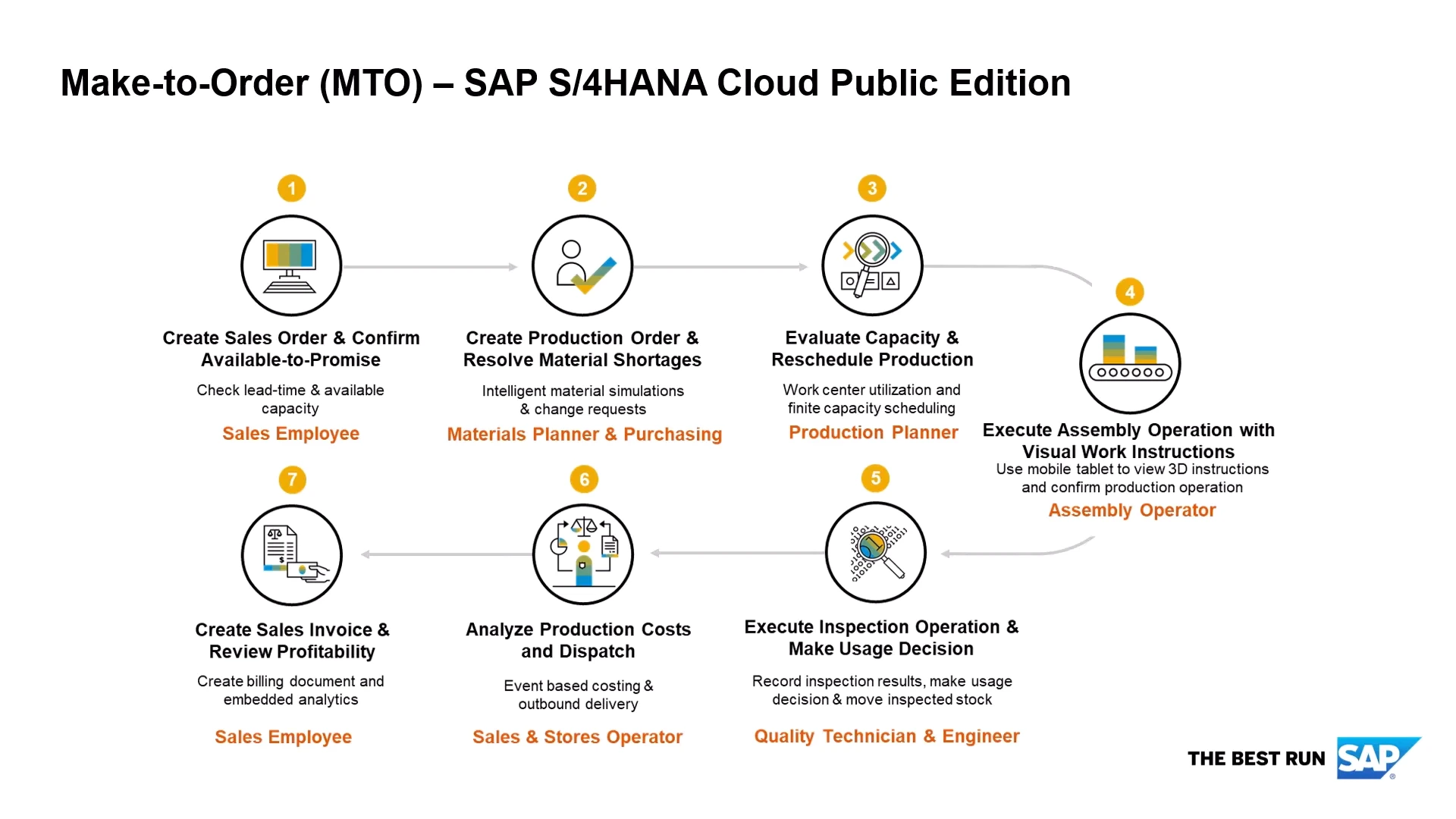

The Make-to-Order (MTO) process in SAP/4HANA Cloud Public Edition is designed to streamline manufacturing operations by producing goods only after receiving specific customer orders. This approach ensures that production is closely aligned with actual demand, minimizing excess inventory and optimizing resource utilization. Below is a detailed breakdown of the MTO process, illustrated through a process flow diagram and accompanied by comprehensive descriptions of each step, roles involved, SAP functionalities utilized, and system configurations.

- Create Sales Order & Confirm Available-to-Promise (aATP): The sales employee creates a sales order and uses the advanced available-to-promise (aATP) functionality to check lead-time and available capacity, ensuring an accurate delivery confirmation date for the customer.

- Create Production Order & Resolve Material Shortages: The materials planner creates a production order. If there are material shortages, intelligent material simulations are used to generate change requests.

- Evaluate Capacity & Reschedule Production: The production planner evaluates capacity and reschedules the production order using work center utilization and finite capacity scheduling.

- Execute Assembly Operation with Visual Work Instructions: The assembly operator uses a mobile tablet to review 3D animated work instructions via SAP Visual Enterprise’s viewer. The operator confirms the completion of the operation and backflushes the materials consumed.

- Execute Inspection Operation & Make Usage Decision: The quality technician conducts the final inspection and records the inspection results. The quality engineer makes a usage decision, moving the stock from “Quality Inspection” to “Unrestricted Use,” and informs sales via MS Teams.

- Analyze Production Costs and Dispatch: Sales checks the order progress and analyzes production costs. The outbound delivery is released to stores, where the stores operator picks the product, posts the goods issue, and produces the dispatch note.

- Create Sales Invoice & Review Profitability: The sales employee creates the sales invoice and uses embedded analytics to review the profitability of the order.