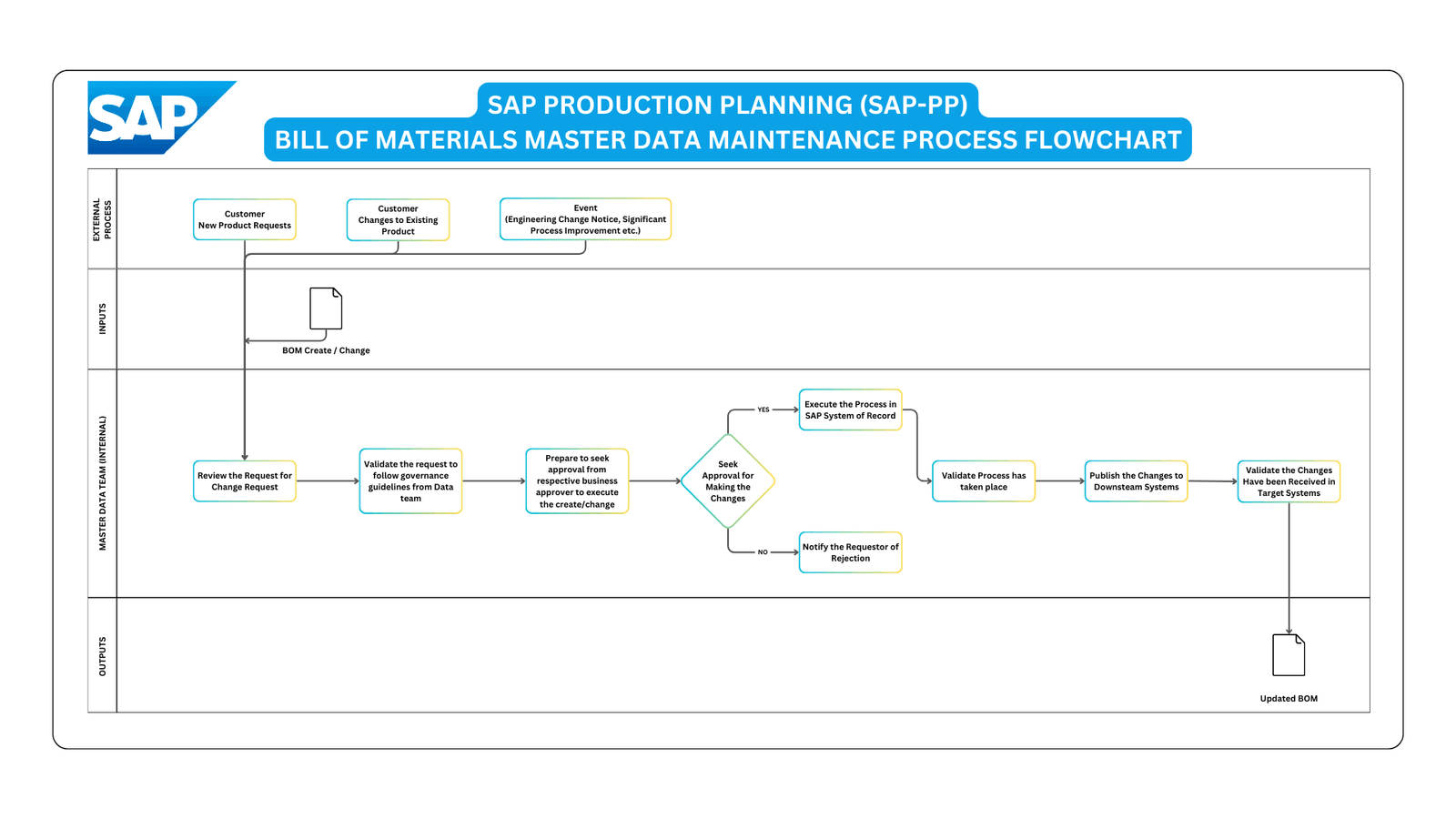

This flowchart illustrates the SAP Production Planning (SAP-PP) process for maintaining the Bill of Materials (BOM) Master Data. It is an organized visual representation of the entire sequence from receiving a request to final update.

A Bill of Materials (BOM) in SAP serves as comprehensive list of components or raw materials needed to manufacture an end-item or sub-assembly. Depending on their purpose, BOMs are categorized into several types such as Engineering BOMs, Sales BOMs, Manufacturing BOMs, and Service BOMs. BOMs can be structured in a hierarchical fashion, providing information on each component level and their quantities.

Detailed Flowchart Description:

- Start: The process begins with an event trigger, which can be a customer request for a new product, customer-driven changes to an existing product, or engineering changes requiring significant manufacturing modifications.

- BOM Creation/Change Request: The process starts with the creation or change of a BOM requested by relevant parties (customer or engineering), which indicates the need for either a new BOM or updates to an existing one.

- Review and Validate Request: The request is reviewed by the appropriate department to ensure it aligns with current standards and practices. Validation ensures that the information provided is complete and accurate before proceeding.

- Preparation for Implementation: Preparatory actions are conducted, which involve preparing the new or changed BOM for implementation within the SAP system. This often involves data cleansing and structuring to meet BOM standards.

- SAP System Execution: The execution step involves incorporating changes into the SAP system using relevant transaction codes (as mentioned in the pages CS01 for creation, CS02 for changes).

- Request for Changes Approval: Once changes are inputted, they are subject to approval processes, ensuring that the changes follow company protocols and do not disrupt ongoing production processes.

- Validation and Publication: Post-implementation, validation checks are conducted to confirm that changes have been successfully implemented. This is followed by publishing these changes across relevant domains to synchronize data.

- Change Notification and System Update: Notifications are sent to relevant parties about the updates. The final step involves updating target systems with the validated BOM changes ensuring all systems are aligned.

The flowchart succinctly outlines critical steps involved the modification and maintenance of BOM in SAP Production Planning. This process ensures that any new or updated BOM continually supports efficient manufacturing operations and maintains data integrity across systems. Each step involves specific transactions and validations to ensure smooth integration and operational continuity.