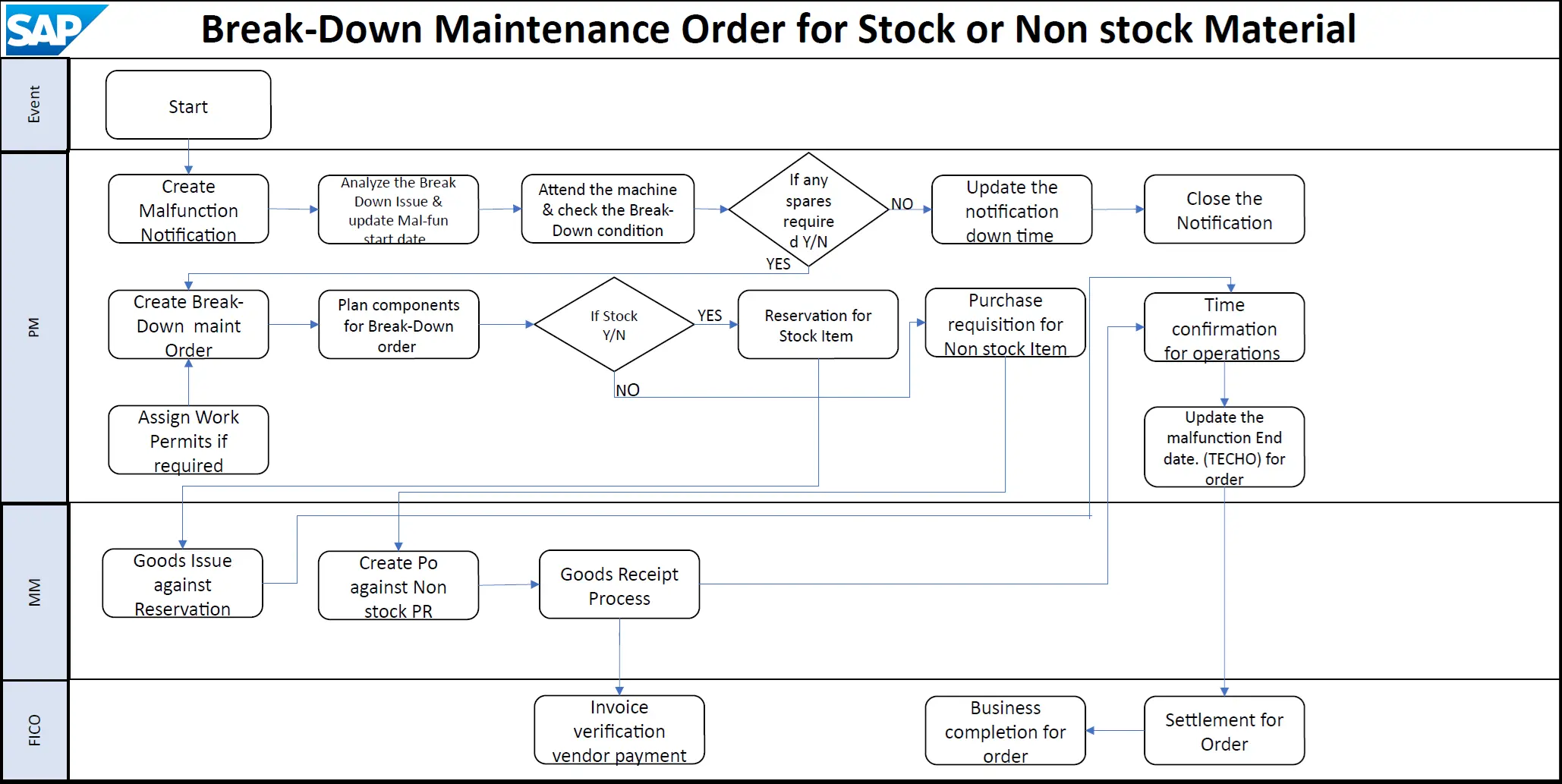

The flowchart illustrates the Break-Down Maintenance Order process for Stock or Non-stock Material within an SAP system, covering integrated modules like PM (Plant Maintenance), MM (Materials Management), and FICO (Financial Accounting & Controlling). Below is a detailed breakdown of the flowchart’s steps:

🛠️ Plant Maintenance (PM) Activities

- Create Malfunction Notification (Transaction Code: IW21): A malfunction notification is created to document the breakdown.

- Analyze the Break-Down Issue & Update Mal-fun Start Date: The maintenance team analyzes the breakdown and updates the malfunction start date.

- Attend the Machine & Check the Break-Down Condition: Technicians physically inspect the machine to assess the breakdown condition.

- If Any Spares Required? (Yes/No): A decision is made on whether spare parts are needed:

- Yes: Proceed to create a break-down maintenance order.

- No: If no spares are required, the notification downtime is updated, and the notification is closed.

- Create Break-Down Maintenance Order (Transaction Code: IW31): A break-down maintenance order is created based on the analysis.

- Assign Work Permits if Required: If necessary, work permits are assigned to the maintenance order.

- Plan Components for Break-Down Order: Planning for the required components begins.

- Stocks Available? (Yes/No): A decision is made on whether the required components are in stock:

- Yes: A Reservation for Stock Item is created (Transaction: MB21).

- No: A Purchase Requisition for Non-stock Item is generated.

- Time Confirmation for Operations (Transaction: IW41): Work time is recorded and confirmed for task completion.

- Update the Malfunction End Date (TECO) for Order: The malfunction end date is updated, marking the technical completion of the order.

📦 Materials Management (MM) Actions

- Goods Issue against Reservation (Transaction Code: MB1A): The goods issue process is triggered for stock items reserved for the maintenance order.

- Create PO against Non-stock PR (Transaction Code: ME21N): A purchase order is created based on the purchase requisition for non-stock items.

- Goods Receipt Process (Transaction Code: MIGO): The goods receipt process is carried out for received non-stock materials.

💰 Finance/Controlling (FICO) Steps

- Invoice Verification (Transaction: MIRO): Process vendor invoices for purchased materials.

- Business Completion for Order: Finalize the order from a business perspective.

- Settlement for Order (Transaction: KO88): Settle costs associated with the maintenance order.

🔗 Key Integration Points:

- PM to MM: Material requirements trigger goods issue or purchase processes.

- MM to FICO: Material movements and purchases initiate financial transactions.

- PM to FICO: Completed maintenance orders are settled in the controlling module.

📚 Related SAP Documentation:

- SAP PM Breakdown Maintenance Guide

- SAP PM Manual: Corrective Maintenance Process

- SAP PM End User Manuals Collection

This description demonstrates the cross-module integration in SAP for managing breakdown maintenance orders, emphasizing the importance of coordinated processes across different functional areas while providing relevant transaction codes for key steps.